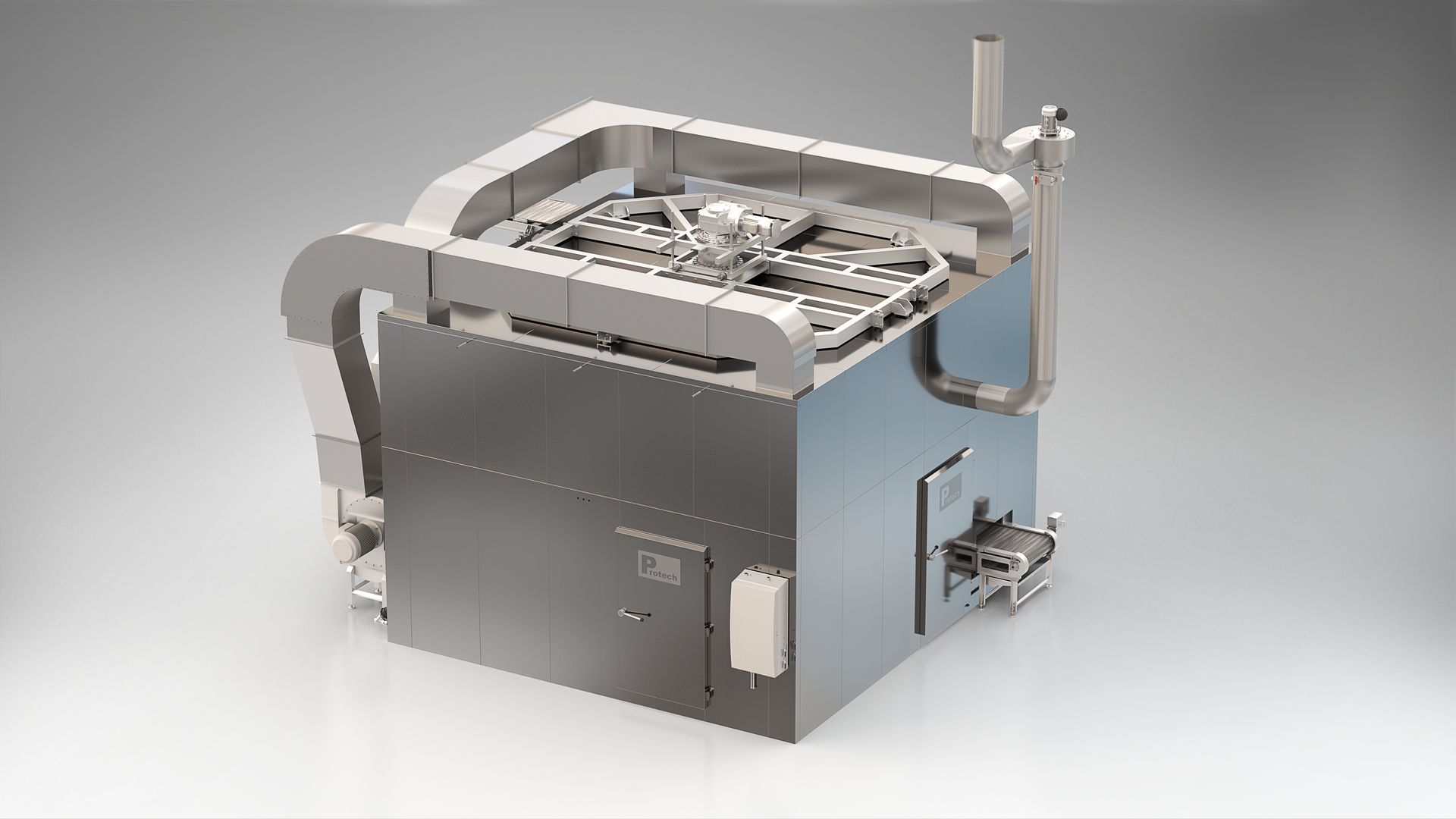

Natural Smoke Spiral System

Smoking/Cooking/Chilling

Equipment Highlights

- Versatile Natural Smoke Design: Using natural smoke, our spiral systems achieve any desired taste, texture, and color comparable to traditional batch smokehouses for products ranging from bacon to smoked salmon and any other products treated in a traditional chamber.

- High-Capacity Smoking System: Our system can produce 10,000+ Lbs. of bacon an hour

- Superior Product Movement and Logistics: Pork bellies move seamlessly via conveyors from brine injectors through the entire spiral system, resulting in fully smoked, cooked, and frozen bacon. This method eliminates the need for rail systems and manual labor to transport bacon to and from batch smokehouses, significantly increasing production efficiency.

- No Combing or Hanging Required: Our spiral systems eliminate the need for combing and hanging, thereby increasing the yield of #1 bacon and reducing labor requirements. By preventing product damage that can occur from impaling pork bellies with hooks, our spirals maintain the integrity of the product.

- Consistent Treatment of Each Pork Belly: Every pork belly is exposed to the same temperature and smoke conditions, resulting in a more consistent product compared to batch smokehouses, which cannot maintain uniform temperature and smoke concentration.

- Customizable to Customer Specifications (Smaller and Larger Throughputs Available): Each line is built to meet the specific needs of our clients, with customization options that include the number of drying, smoking, and freezing spirals, layout direction, optional liquid smoke drench, and variable throughput to suit different production demands.

Benefits

Labor Savings ($2.4M saved annually)*:

BAK’s design successfully reduced labor requirements from 50 employees to less than 2 per line (3 over 2 lines). Assuming a total cost per employee of $50,000, the savings are over $2 Million dollars per year. Click for calculation details

More #1 bacon ($7.5M to $11.2M saved annually)

Due to consistent treatment and no hanging, the spiral system results in significantly more #1 bacon. Assuming a yield of 80% for #1 bacon and 15% for #2 bacon (95% total) in traditional processes vs (88%,5%) to (93%,3%) for the spirals (96% total), the resulting savings are in the range of $7.5M to $11M per year. Click for calculation details

Utility Savings

While difficult to quantify precisely, BAK estimates significant savings on energy. Due to the design of our system, our chambers maintain their temperature throughout production, whereas traditional batch houses must cool down and reheat after each batch.

Floor Space

Up to 60% reduction of required floor space

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments. Current lines in operation run 110+ hours a week.

Advanced Programmable Control Panel:

Our advanced programmable control system allows for the creation of customized programs tailored to specific product requirements. Parameters such as dwell time, smoke density, and temperature can be precisely controlled through the intuitive HMI, ensuring optimal results for each product.

Easy Cleaning and Maintenance:

Designed with a fully integrated Clean-In-Place system.

Applications

Our automated natural smoking, cooking, chilling line is designed to provide fully automated, high-efficiency processing for a wide range of smoked products. It excels in handling popular items like bacon, salmon, and ribs, ensuring consistent quality and flavor across large production volumes. The system is versatile and can be easily adapted to accommodate various other products.