Series MH

SAS Brine Injectors

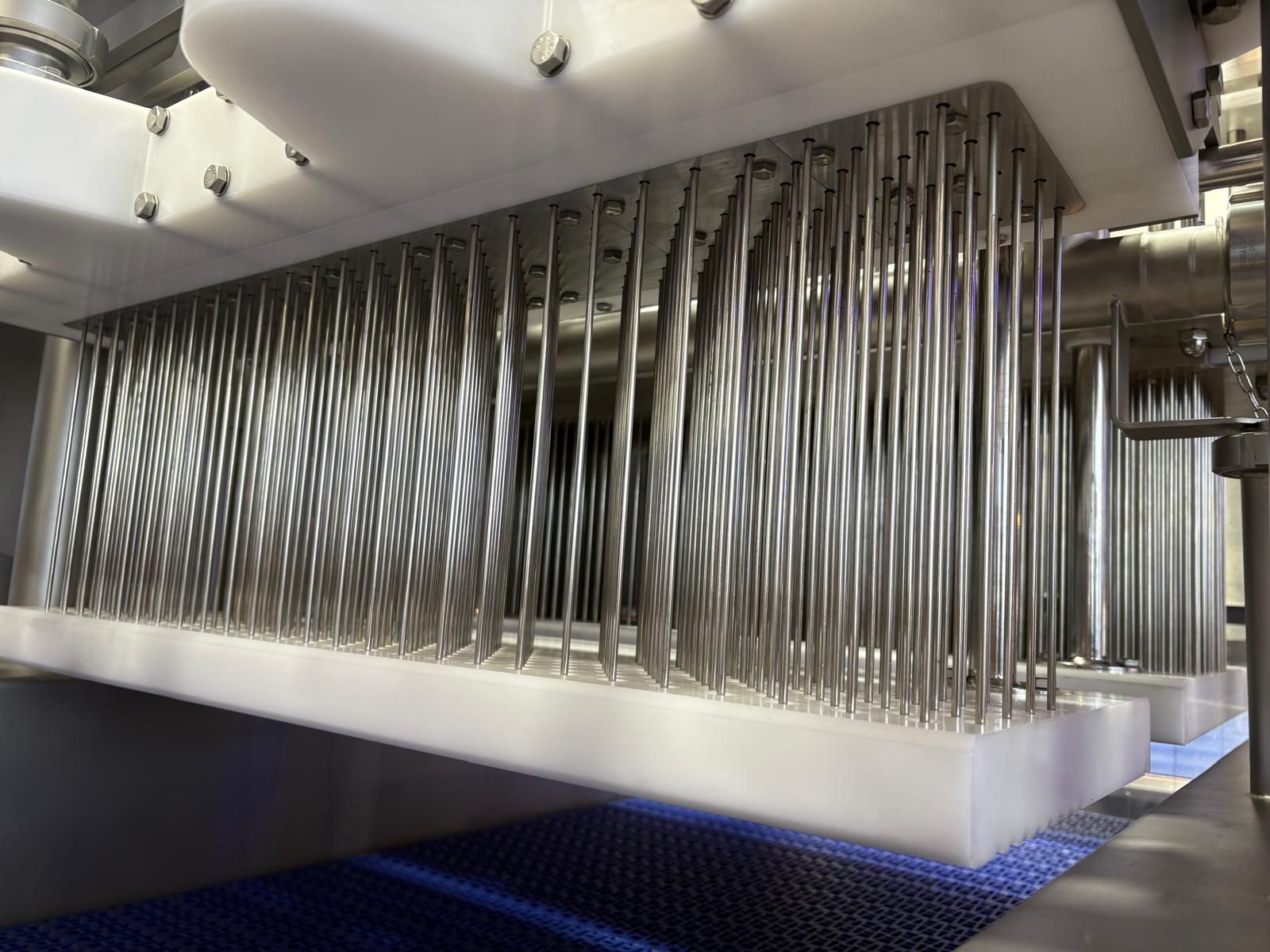

Needles

117 to 1,480

Needles

Conveyor Width

18 - 41

In.

- High-Performance Servo Design: Powered by servo motors, enabling the machine to handle high workloads with precision and consistency.

- Variable Parameter Control: Easily adjust all injection parameters such as injection stroke length, duration of injection, position of injection (on descent or ascent of the head), injection head speed, speed of the belt, and brine pump pressure. The machine is capable of operating at any setting within its full range, ensuring optimal performance for your specific needs.

- Bone-In or Boneless Capability: The machine is designed to efficiently handle both bone-in and boneless products, offering versatility for various processing needs.

- Ergonomic Injector Head Handling: A new crank-and-rail arm system allows for safer, easier handling of the injector head—minimizing strain and improving operator efficiency.

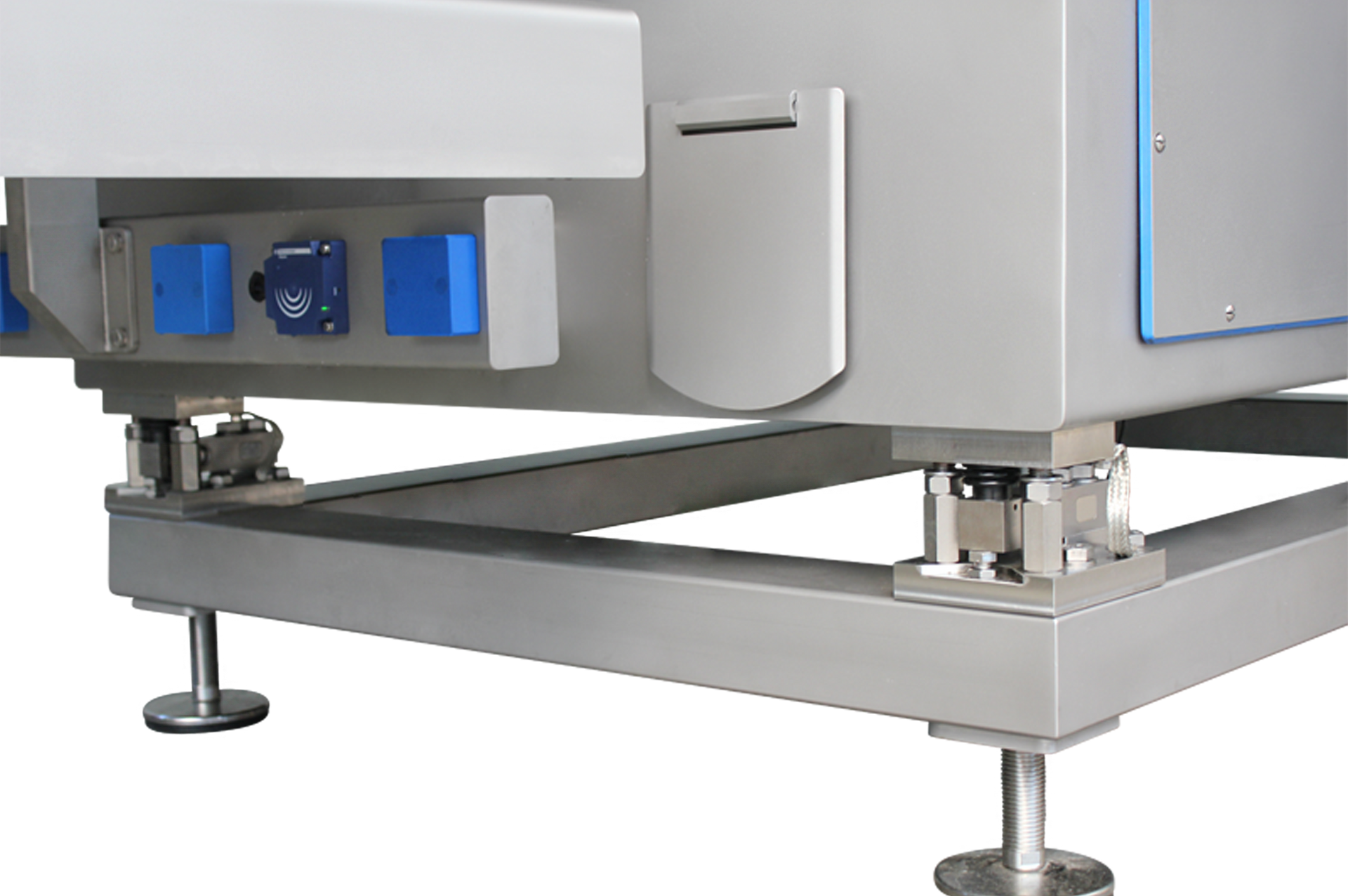

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store 99 custom programs by adjusting variables such as injection stroke length, duration of injection, position of injection (on descent or ascent of the head), injection head speed, speed of the belt, and brine pump pressure.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient. The needle heads and individual needles can easily be removed for cleaning and maintenance

Technical Information

MH 660 and MH 1480 needle configurations were specially design for fish products

Regular

Fish Oriented

Applications

NOMA SAS Brine Injectors are designed for high-production brine injection across a variety of products, including bone-in or boneless meats, whole poultry and poultry parts, as well as fish and fish fillets. These injectors ensure consistent flavor and moisture distribution, delivering reliable results for large-scale operations.