Resources

Case Studies

Videos

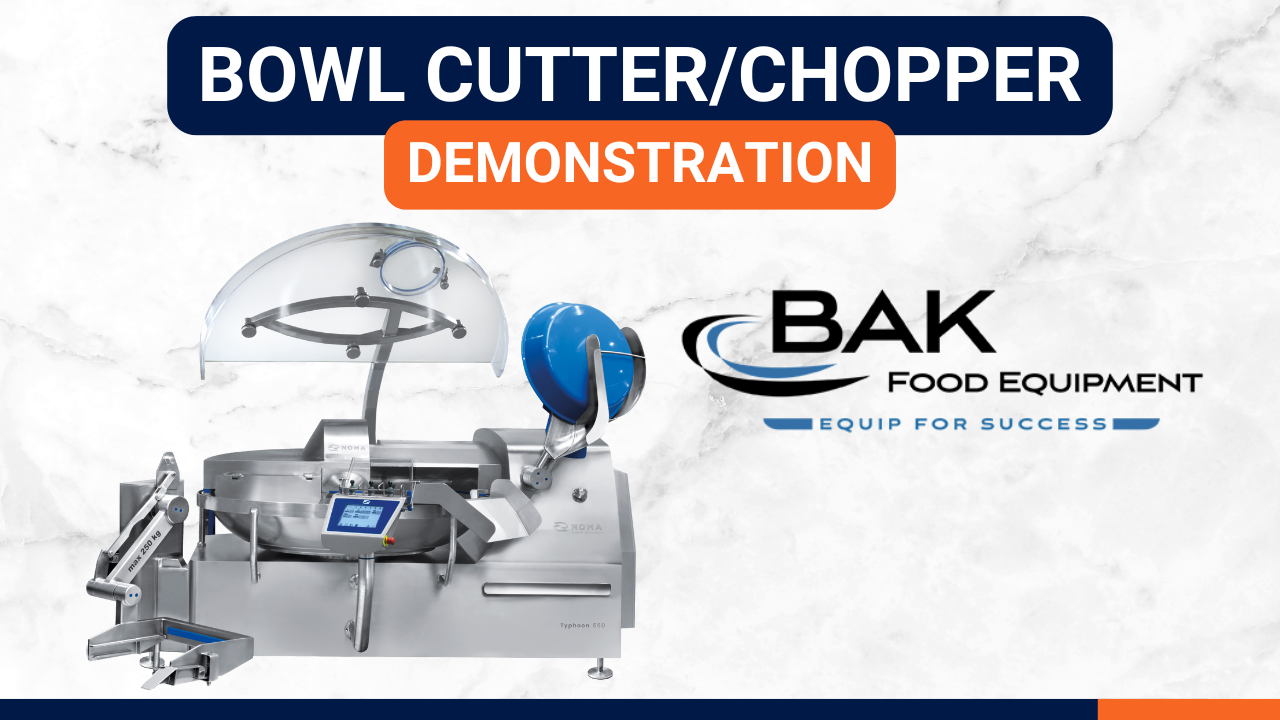

This demonstration highlights how products processed by the Bowl Cutter/Chopper offer significant advantages, such as... Enhanced Texture and Consistency : Achieve finely ground, uniformly processed products that are ideal for a range of applications. Increased Product Yield: The cutting process maximizes ingredient integration, ensuring minimal waste while maintaining high quality. Customization and Precision: Adjust rotation speed and direction to achieve the perfect texture for sausages, pâtés, and other ground products, offering unmatched flexibility for product innovation. With precise control over cutting speed, temperature, and texture, the Bowl Cutter ensures uniformity, improves product consistency, and enhances the overall quality across various food types.

Articles

As global food demand increases, many food processors find themselves struggling to keep up and stay competitive with their current operations. Historically, the food processing industry has lagged in adopting automation, largely due to misconceptions that such technology diminishes food quality and increases costs. However, automated food processing equipment can provide the crucial boost needed to maintain a competitive edge. Automation Unveiled: Unlocking Benefits for Your Business Zack Olson, the manager of growth strategy and innovation at BAK Food Equipment , addresses these misconceptions in a compelling 20-minute webinar . Available now for on-demand viewing, Olson’s presentation explores the benefits of automation for food processors. He dismantles common myths and shares real-life success stories of food processing operations that have significantly increased output and improved employee retention by integrating just a single piece of automated equipment. Solving Labor Challenges One of the most pressing issues for many food processors is labor constraints. For example, a bacon production line can require up to 40 workers from start to finish. Automated solutions can reduce this number to just two, freeing up the remaining employees for other essential tasks. This transformation is especially beneficial in small towns where labor is scarce. Additionally, automation helps reduce employee injuries and improves retention by minimizing physically demanding tasks. Enhancing Quality and Consistency Automation also brings significant improvements in product quality and consistency. By minimizing human intervention, automated systems ensure that all measurements are precise, and each batch of product receives identical treatment. For instance, many processors have found that using a multi-needle, automated brine injector ensures more even distribution of brine throughout cuts of meat compared to the traditional manual injection with a single needle. I mproving Food Safety and Reducing Waste Furthermore, automation plays a critical role in reducing waste and enhancing food safety. With fewer opportunities for human error, the risk of product contamination or mishandling decreases. Additionally, most automated equipment comes with built-in data logging capabilities, which increase traceability and further bolster food safety measures. By embracing automation, food processors can address labor shortages, enhance product quality and consistency, and improve overall food safety. To learn more about the transformative potential of automated food processing equipment, watch Zack Olson’s informative webinar, now available on-demand from BAK Food Equipment . Learn More Food processors interested in learning more about the benefits of automation and how to optimize their operations can view the on-demand video here . As the exclusive North American distributor of NOMA (formerly Nowicki Food Machinery), N&N Nadratowski, and Protech food processing equipment, BAK Food Equipment provides the highest quality tumblers , meat injectors , meat grinders , and more. With a dedicated team of knowledgeable sales staff, talented engineers, and expert service technicians, BAK Food Equipment also offers installation, design, engineering, and service. About BAK Food Equipment BAK Food Equipment, previously known as Equipment Processing Solutions, carries a broad line of food processing equipment, including industrial mixers, grinders, cutters, tumblers and tenderizers, injection systems, and monitoring hardware. With more than 60 years of experience in the food industry, BAK Food Equipment partners with its customers from initial consultation through design and specification to provide the right food processing equipment at the best value. BAK Food Equipment is the exclusive North American distributor of NOMA, Protech, and N&N Nadratowski food processing solutions. To learn more, visit www.bakfoodequipment.com .

Blogs

BAK Food Equipment is pleased to announce that Zack Olson has joined the team as Sales and Marketing Specialist. In this new role, Olson will work closely with Thomas Bako , Director of Business Development, to grow the sales pipeline while also supporting BAK Food Equipment’s existing client relationships. Olson graduated from the University of Chicago in 2022 with a degree in Economics. While there, Olson was a first-team all-conference wide receiver on the school’s football team. He comes to BAK Food Equipment from Oliver Wyman, where he worked in the Private Capital Division with a focus on companies in the aerospace and defense industries. In this role, Olson worked with top-level executives and C-suite management from companies of all sizes. “Zack brings an infectious enthusiasm to BAK Food Equipment and will work alongside Tom Bako to develop exciting marketing efforts that help grow and nurture our sales pipeline,” said John Bobak, founder and CEO of BAK Food Equipment. “We are thrilled to welcome him to our team.”