Automated Mixing Grinding Line for Automated Meat Processing

Equipment Highlights

Automatic Microprocessor Controlled

The mixing-grinding line and its control system is designed and built around the customers production needs.

Simple to Complex Setups

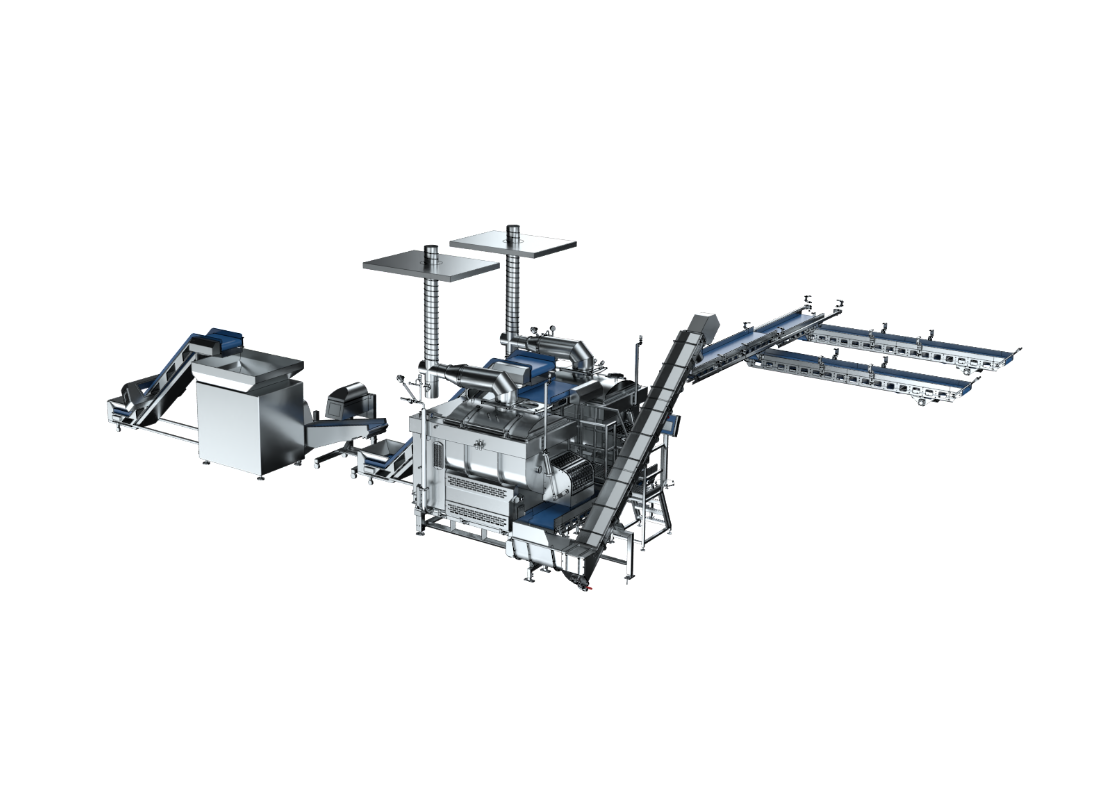

Lines are designed to meet each customer’s unique needs, ranging from simple to highly complex setups. They can integrate a variety of components such as grinders, mixers, mixer-grinders, mix-cook units, emulsifiers, metal detection equipment, and more ensuring an efficient and tailored solution for your production process.

Customizable Size and Capability

BAK can supply machines of any size within our portfolio to integrate into your production line. We can also design systems around any number of units to meet your desired throughput requirements.

Benefits

Increased Production Capability

Automation significantly reduces manual labor, speeding up the process and allowing for higher production output.

Consistent Product Quality

Automated systems ensure consistent product quality. Each batch is treated the exact same way from start to finish.

Improved Hygiene and Food Safety

Automated systems reduce the need for manual handling, lowering the risk of contamination and enhancing food safety standards

Labor Efficiency

Fewer operators are required to manage the process, reducing labor costs while maintaining high throughput.

Why Choose BAK

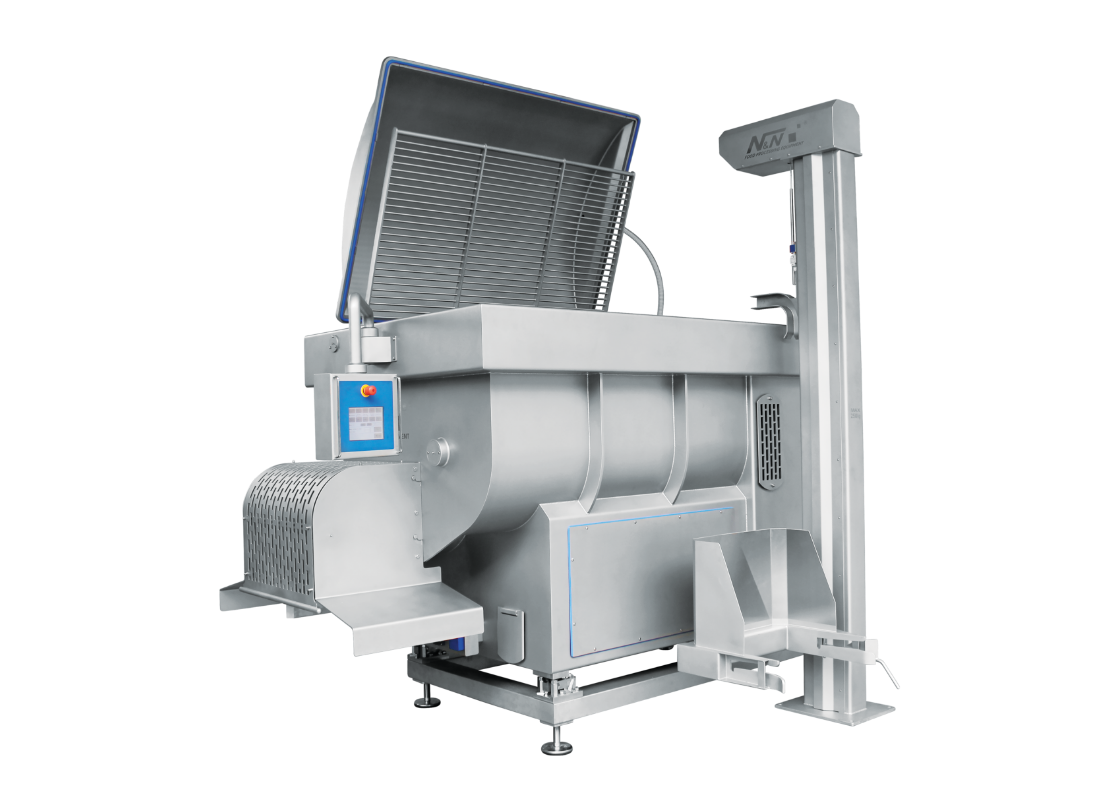

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

The mixing-grinding line and its control system is designed and built around the customers production needs.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Applications

Our automated mixing-grinding lines are ideal for processing various products, including various proteins, meat stuffings, sausages, burgers, salads, vegetables, fruits, sauces, cheeses, doughs, pet food, and more. By integrating mixing and grinding into a seamless process, these lines reduce human error and labor to ensure consistent high-quality results batch after batch.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to Automated Meat Processing

What is automated meat processing?

Automated meat processing refers to the use of advanced technology and industrial food processing equipment to perform tasks that were traditionally done by hand, such as mixing, grinding, injecting, chopping, or emulsifying meat products. By leveraging automation, businesses can significantly increase production throughput per employee, reduce manual labor, and ensure consistent product quality. Automation in meat processing often involves connecting standalone machines into integrated automated production lines, allowing for seamless operation and improved efficiency across the entire process.

How does a mixing-grinding line fit into this process?

A mixing-grinding line is a core automation step for many food products that require both mixing and grinding. In an automated mixing-grinding line, equipment such as grinders, mixers, mixer-grinders, and even mix-cook units are connected—often via conveyors and a unified human-machine interface (HMI)—to eliminate not only manual mixing and grinding but also the manual transfer of products between machines. This integration streamlines production, reduces human error, and ensures each batch is processed in exactly the same way, resulting in consistent, high-quality output. BAK Food Equipment’s automated mixing-grinding lines are customizable to fit any production scale, from simple setups to highly complex systems, and can be tailored to meet specific throughput requirements.

Why are businesses shifting to automation?

The shift toward automation in meat processing is driven by both necessity and strategy. Many operators are adopting automation because of labor shortages—when it’s difficult to find enough skilled employees, automation becomes the only viable way to keep operations running smoothly. Strategically, automation offers significant benefits: it reduces labor costs, increases production capability, and delivers consistent batch-to-batch product quality. Automated systems also improve hygiene and food safety by minimizing manual handling, and their durable, industrial-grade construction ensures long-lasting performance. Ultimately, automation enables businesses to achieve higher profits and maintain a competitive edge in the market by producing more with less labor and maintaining superior product standards.

Are you looking for another aspect of meat and/or food processing automation? Explore BAK custom automation solutions and the rest of our equipment portfolio.

Features of the Automated Mixing Grinding Line

What makes a BAK Food Equipment Mixing Grinding Line unique?

BAK Food Equipment’s automated mixing grinding line stands out for its advanced microprocessor-controlled automation, which is designed and built around each customer’s specific production needs. This technology ensures that every batch is processed with precision, resulting in consistent product quality and significantly reducing the risk of human error. The system’s stainless steel construction not only guarantees exceptional durability but also supports the highest standards of hygiene and food safety, as it minimizes manual handling and the associated risk of contamination. Additionally, the line is engineered for easy cleaning and maintenance, making it a practical choice for demanding food processing environments.

How customizable is it?

One of the defining features of BAK’s automated mixing grinding line is its high degree of customization. Whether a customer requires a straightforward setup—such as a single mixer and grinder—or a more complex configuration involving multiple mixers, grinders, mixer-grinders, and other processing units, the system can be tailored to fit. BAK can supply machines of any size from its portfolio and design systems around any number of units to meet specific throughput requirements. This flexibility allows food processors to scale their operations efficiently and adapt to changing production demands, making the equipment suitable for a wide range of applications, from meat stuffings and sausages to salads, cheeses, and pet food.

What equipment can be integrated into the system?

The automated mixing grinding line is designed for seamless integration with a variety of equipment, enhancing both functionality and efficiency. Integrations include mixers, automated meat grinders, mixer grinders, emulsifiers, mix-cook units, metal detection equipment, and many more start of line or end of line pieces of equipment. These integrations enable processors to create a fully automated, end-to-end solution that not only increases production capability but also ensures product safety and quality. By leveraging food automation technology and customizable production equipment, BAK helps customers build lines that are perfectly aligned with their operational goals and regulatory requirements.

Benefits of Automated Meat Processing with BAK

How does automation improve productivity and efficiency?

Automation in meat processing, as delivered by BAK Food Equipment, dramatically enhances productivity and efficiency by streamlining operations and reducing the need for manual labor. Automated mixing and grinding lines are designed to meet each customer’s unique production requirements, whether for simple or highly complex setups. By integrating components such as grinders, mixers, mixer-grinders, and more, BAK’s systems enable higher production throughput with fewer operators. This means that facilities can process more product in less time, while also minimizing the risk of human error. The advanced programmable control panels allow for precise, repeatable processes, ensuring that every batch is handled identically from start to finish. This not only boosts output but also optimizes labor efficiency in food processing, allowing staff to focus on higher-value tasks.

What role does automation play in food safety?

Food safety is a critical concern in meat processing, and automation plays a pivotal role in maintaining high standards. BAK’s automated systems are engineered to reduce manual handling, which significantly lowers the risk of contamination. By automating key steps in the process, such as mixing and grinding, the opportunity for human contact with the product is minimized, supporting automated food safety protocols. Additionally, the equipment is constructed entirely from stainless steel, making it easy to clean and maintain, further reducing the risk of bacterial growth and cross-contamination. The result is a safer, more hygienic production environment that meets or exceeds industry food safety standards.

What are the cost benefits?

Adopting automated meat processing technology from BAK offers substantial cost savings in meat processing. With fewer operators required to manage the process, labor costs are significantly reduced. Automation also leads to consistent batch-to-batch product quality, which minimizes waste and optimizes ingredient use—directly impacting the bottom line. The durable, industrial-grade construction of BAK’s equipment ensures long-lasting performance, reducing the need for frequent repairs or replacements. Furthermore, the easy cleaning and maintenance features help decrease downtime, keeping production lines running efficiently. All these factors contribute to improved yield and a more cost-effective operation overall.

Industries & Use Cases for Mixing and Grinding Lines

Which industries rely on automated mixing-grinding equipment?

Automated mixing and grinding lines are transforming a diverse range of industries by streamlining production and ensuring consistent, high-quality results. Meat processing plants are among the primary adopters, using these systems for sausage production automation, burger production equipment, snack stick production, and other protein-based products. Prepared foods manufacturers also benefit, as automated mixing lines efficiently handle salads, sauces, and ready-to-eat meals. Bakeries and dough producers leverage automated mixing systems for consistent dough mixing and ingredient integration, while pet food producers rely on automation to meet strict safety and nutritional standards. Dairy operations, too, use automated mixing lines for cheese and other processed dairy products, ensuring uniformity and compliance with food safety regulations.

What business challenges does this technology solve?

Businesses across these industries face several common challenges: labor shortages, stringent food safety regulations, and the need for consistent product quality. Automated mixing-grinding lines directly address these issues by reducing the need for manual labor, which not only helps mitigate workforce shortages but also lowers labor costs. By minimizing human contact during critical processing steps, these systems reduce the risk of contamination and make it easier to comply with strict safety standards. Automation also standardizes recipes and processes, ensuring each batch meets the same high-quality standards and reducing the likelihood of human error. This consistency leads to less downtime, more production hours, and ultimately, increased profitability.

How does it scale to different production environments?

One of the key advantages of BAK Food Equipment’s automated mixing-grinding lines is their scalability and flexibility. These systems are designed to be customizable, with sizes and configurations tailored to match the specific needs of both independent processors and large-scale facilities. Whether a business requires a simple setup or a highly complex, integrated production line, BAK can supply and design solutions that fit any throughput requirement. As production volumes increase, automation helps drive down the cost per pound of product, making it a cost-effective investment for operations of any size. This adaptability ensures that businesses can grow and evolve their production capabilities without needing to overhaul their entire processing infrastructure.

By integrating advanced automation into their operations, companies across the food industry can overcome labor and compliance challenges, achieve consistent product quality, and scale efficiently to meet growing demand.

Why Choose BAK Food Equipment

Industry Expertise in Automated Meat Processing Systems

When selecting a partner for your automated meat processing needs, industry expertise is paramount. BAK Food Equipment brings decades of experience in designing and implementing advanced automated systems for the food industry, starting with BAK's founder who ran a sizable sausage production operation and has since helped hundreds of customers reach their production goals. Our team understands the unique challenges of meat processing, from maintaining product consistency to meeting stringent food safety standards. We leverage this expertise to deliver solutions that not only meet but exceed our clients’ expectations, ensuring your production line operates efficiently and reliably.

Fully Customizable Solutions Designed for Long-Term Performance

Every food processing facility has its own set of requirements, and BAK Food Equipment specializes in providing fully customizable solutions. Whether you need a simple setup or a highly complex, integrated line, our systems are designed around your specific production needs. We offer a wide range of equipment—including grinders, mixers, mixer-grinders, mix-cook units, and more—that can be tailored in size and capability to match your desired throughput. Our machines are constructed from industrial-grade stainless steel, ensuring durability and long-term performance even in the most demanding environments.

In-House Support from Consultation to Installation and Maintenance

Choosing BAK Food Equipment means gaining a true industrial food processing partner. Our support begins with an in-depth consultation to understand your goals and continues through every stage of the project, from design and installation to ongoing maintenance. Our advanced programmable control panels and thoughtfully engineered systems make operation, cleaning, and maintenance straightforward and efficient. With BAK, you benefit from a seamless experience and a dedicated team committed to your success, ensuring your automated production lines deliver consistent, high-quality results batch after batch. Learn more about BAK Food Equipment as an industrial food processing partner by reading our case studies like

snack stick producer case study (mixing-grinding line) and

Large Bacon Processor (Spiral Smoking System).

Automated Mixing & Grinding Line FAQs

What is automated meat processing?

Automated meat processing refers to a broad range of technology-enabled processes designed to increase meat production throughput per employee. It involves the use of industrial food processing equipment to perform tasks such as mixing, grinding, injecting, chopping, and emulsifying—steps that were traditionally carried out by hand. By automating these processes, meat processors can reduce manual labor, improve consistency and quality, enhance food safety, and significantly boost overall throughput.

How does a mixing-grinding line streamline production?

A Mixing-Grinding Line streamlines production by integrating mixing, grinding, and sometimes additional steps such as emulsifying into a single automated workflow. This integration reduces the need for manual intervention, minimizes the risk of human error, and accelerates production cycles. The result is a streamlined operation that delivers consistent, high-quality results batch after batch.

Can the system handle products beyond meat?

Absolutely. While these lines are optimized for proteins, their versatility extends to a wide range of products. BAK’s automated mixing lines can process sauces, cheeses, doughs, salads, vegetables, fruits, and even pet food. This flexibility makes them an excellent choice for processors looking to diversify their product offerings or adapt to changing market demands. For more details on the full range of applications, visit our applications page.

What food safety benefits come with automation?

Automation in mixing and grinding lines brings significant food safety advantages. By reducing manual handling, the risk of contamination is minimized, helping processors meet stringent hygiene standards. The stainless steel construction of BAK’s equipment further supports easy cleaning and maintenance, ensuring that sanitation protocols are straightforward and effective. Automated systems also help maintain compliance with regulatory requirements, giving processors peace of mind regarding food safety.

How does automation lower costs?

Automated mixing-grinding lines deliver cost savings in several ways. First, they reduce the need for manual labor, allowing fewer operators to manage larger volumes of production. Second, automation improves yield and minimizes waste by ensuring precise, repeatable processing. Third, increased throughput means more product can be produced in less time, maximizing operational efficiency. Over time, these factors combine to significantly lower overall operating costs while maintaining or improving product quality.