Series MG

Mixer Grinders

Bowl Volume

450 - 1500

Liters

Max Mixing Capacity

744 - 2480

Pounds

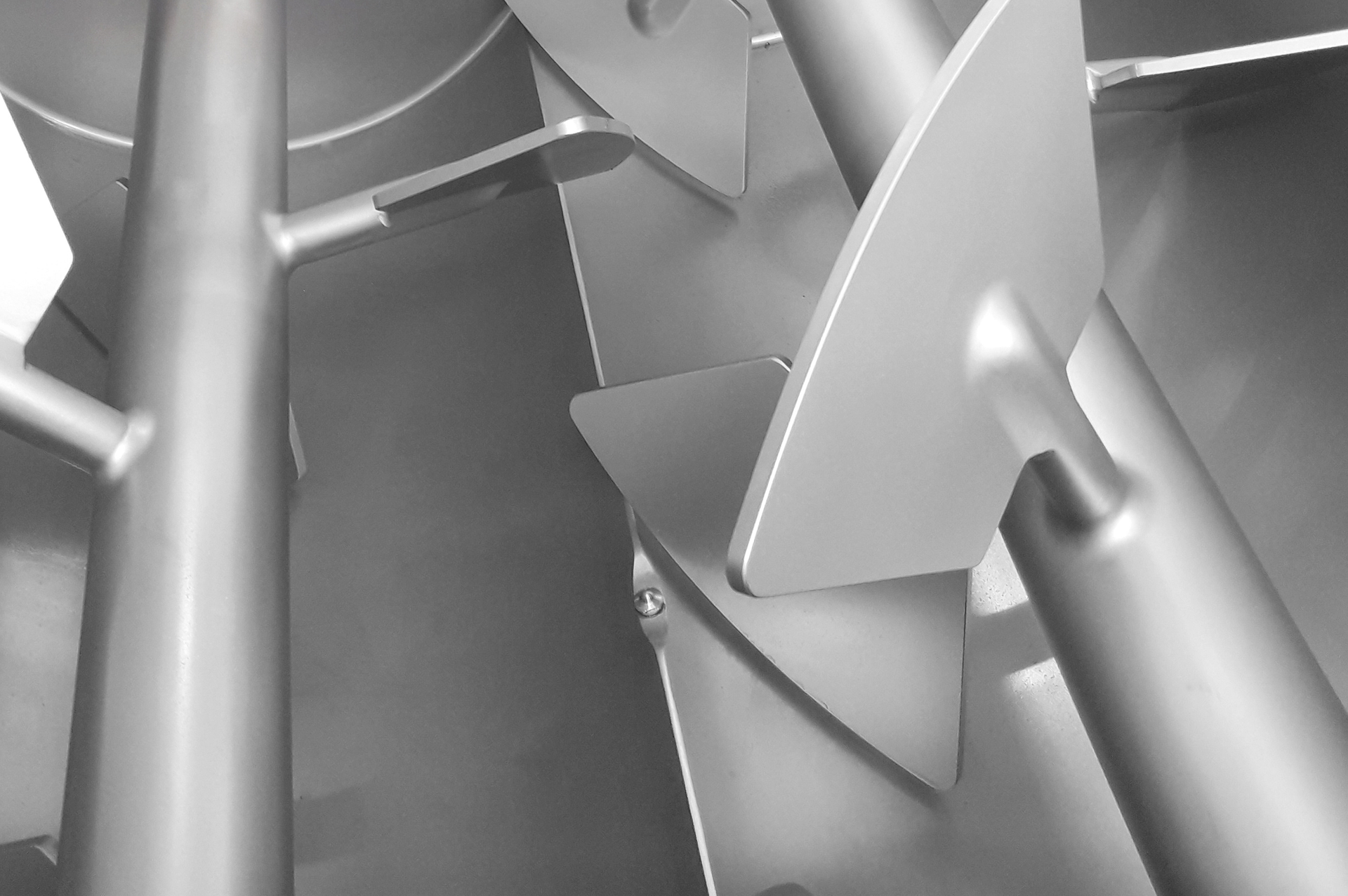

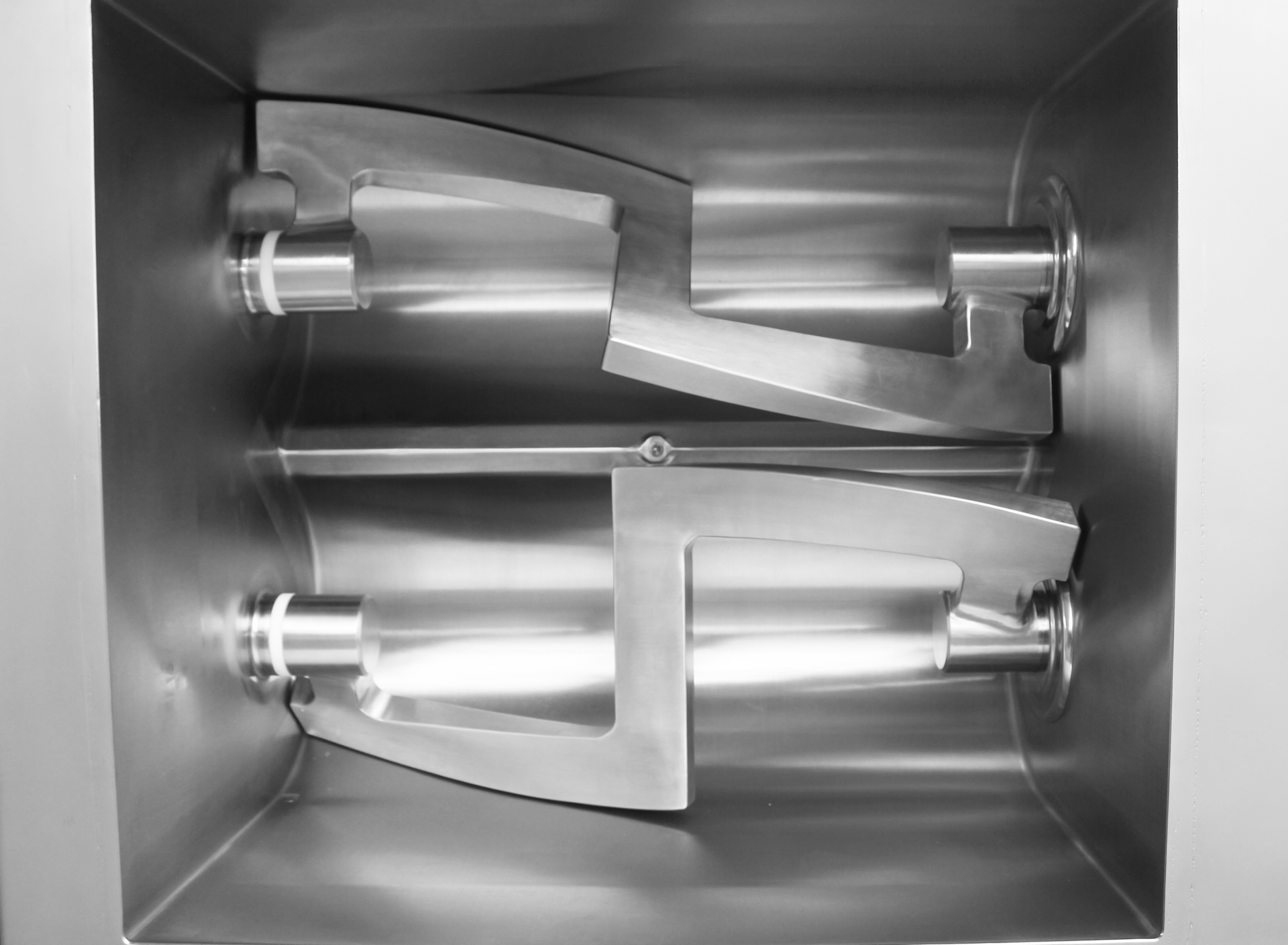

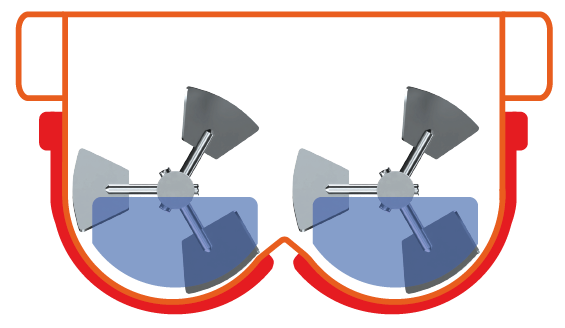

- Advanced Twin-Paddle Mixing System: The twin-paddle shaft mixing system provides gentle yet effective mixing, maintaining the ideal structure of both fatty and lean meats. It ensures up to 20% faster mixing, making it perfect for pre-minced meat and other meat products that require precise mixing and color consistency after grinding.

- Variable speed: Offers precise speed adjustments, allowing the shafts and griding auger to rotate at any desired speed within the machine's range.

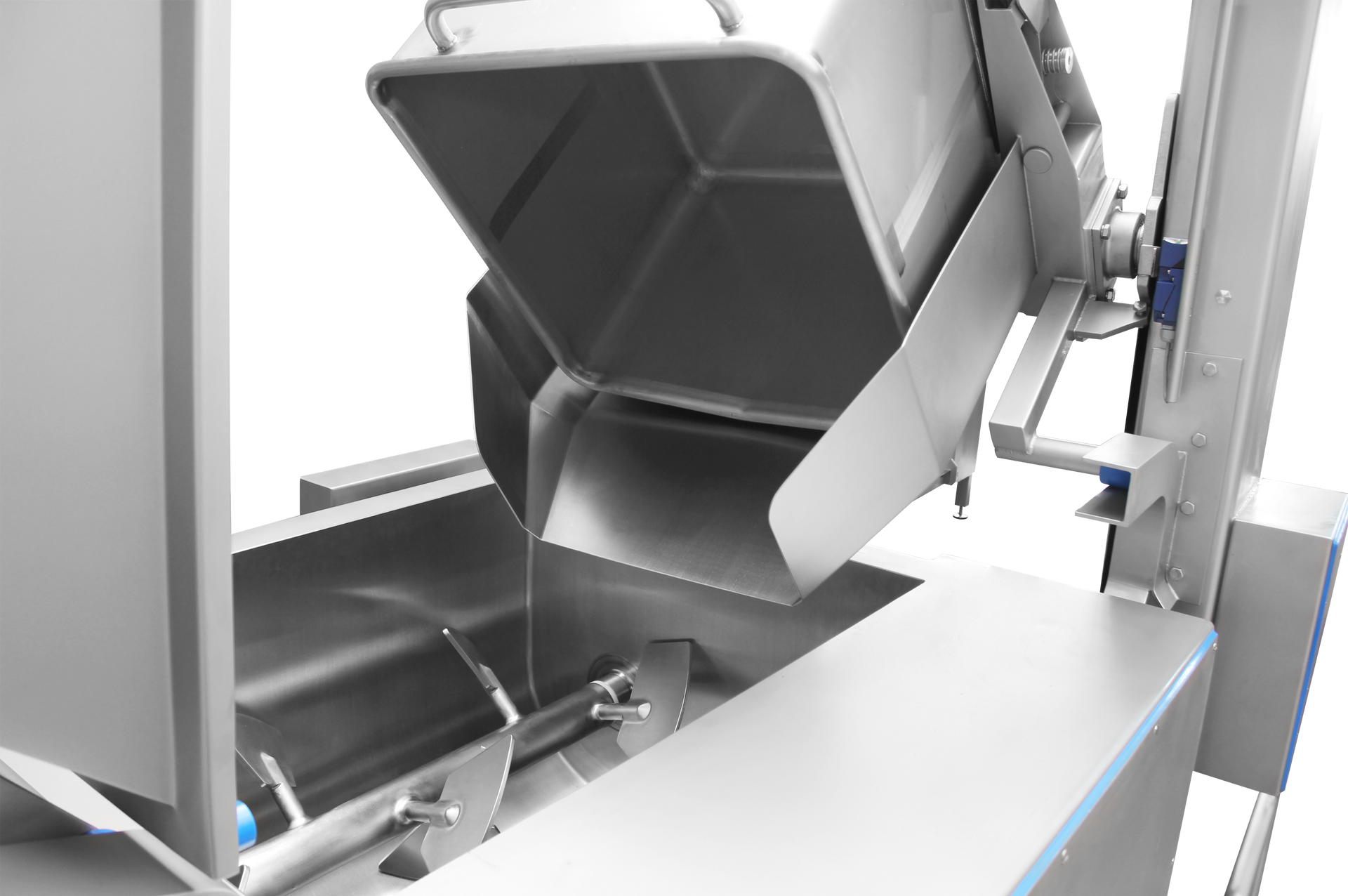

- Direct-Flow Grinder: The MG Series features a grinder positioned directly beneath the mixer tank, allowing pre-minced meat to flow efficiently from the mixer to the grinder. Specially shaped paddles ensure quick filling, minimizing waste and streamlining the grinding process.

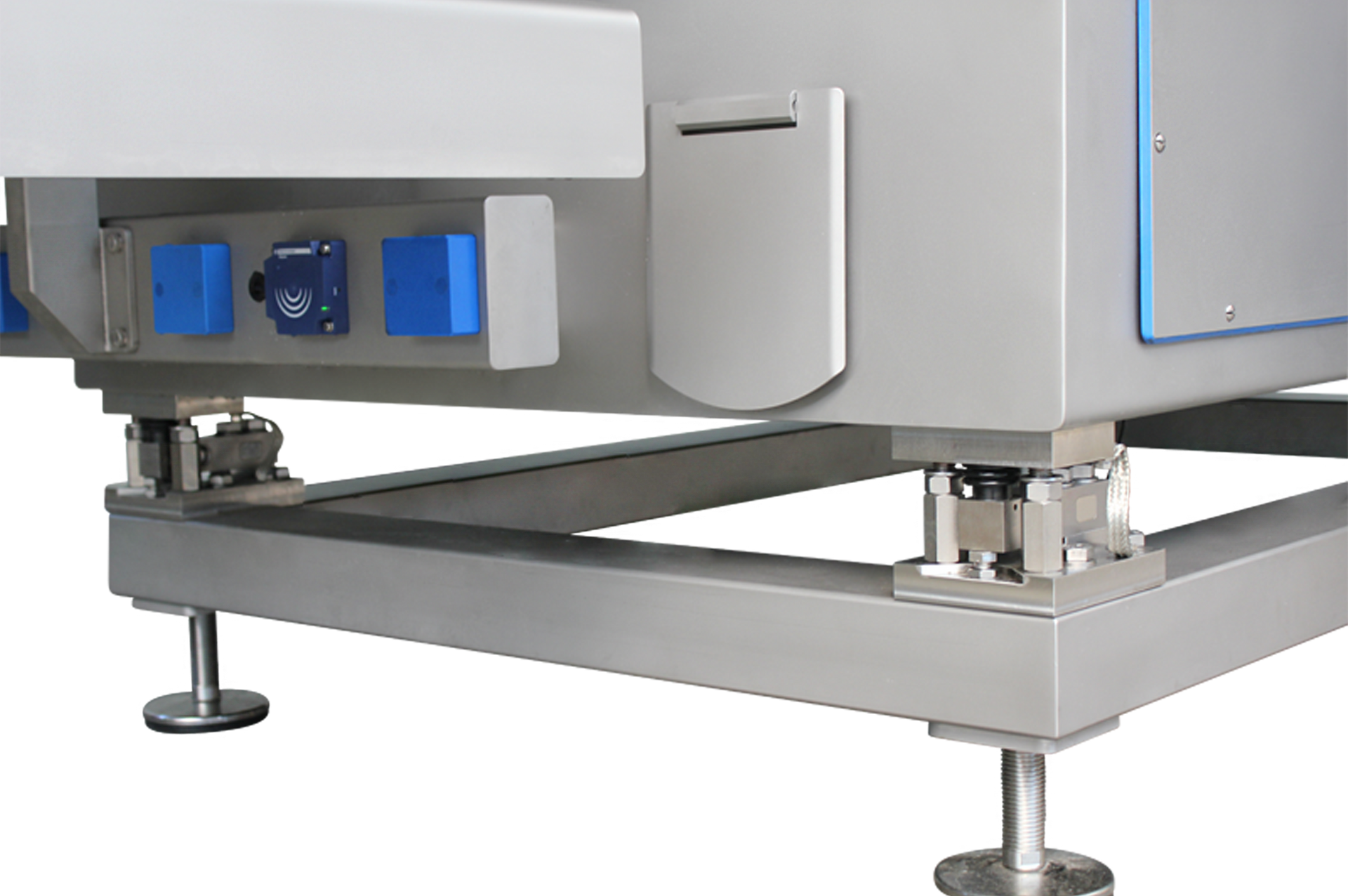

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments. The grinding auger is machined from a single piece of stainless steel.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as mixing and auger speed.

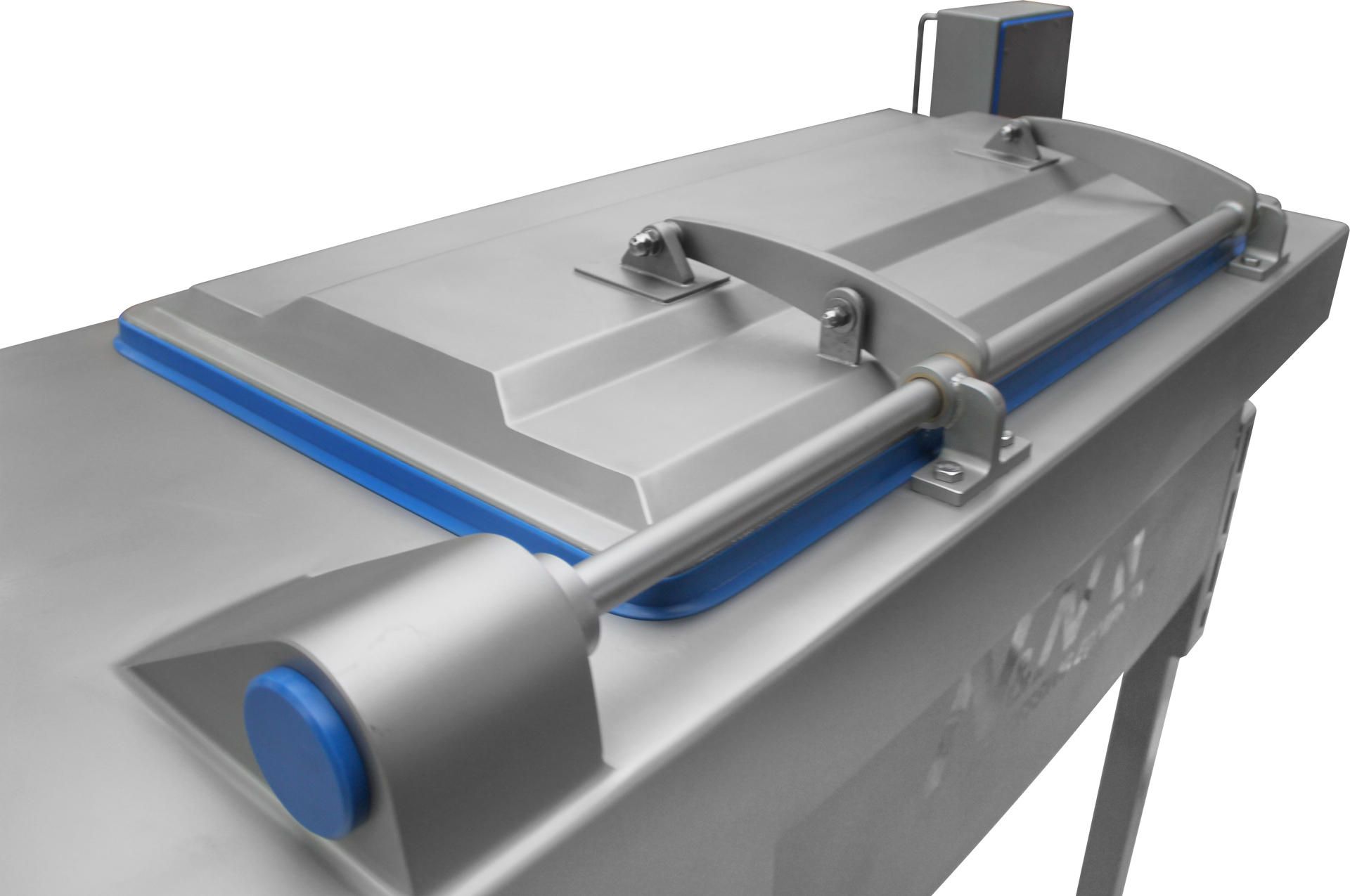

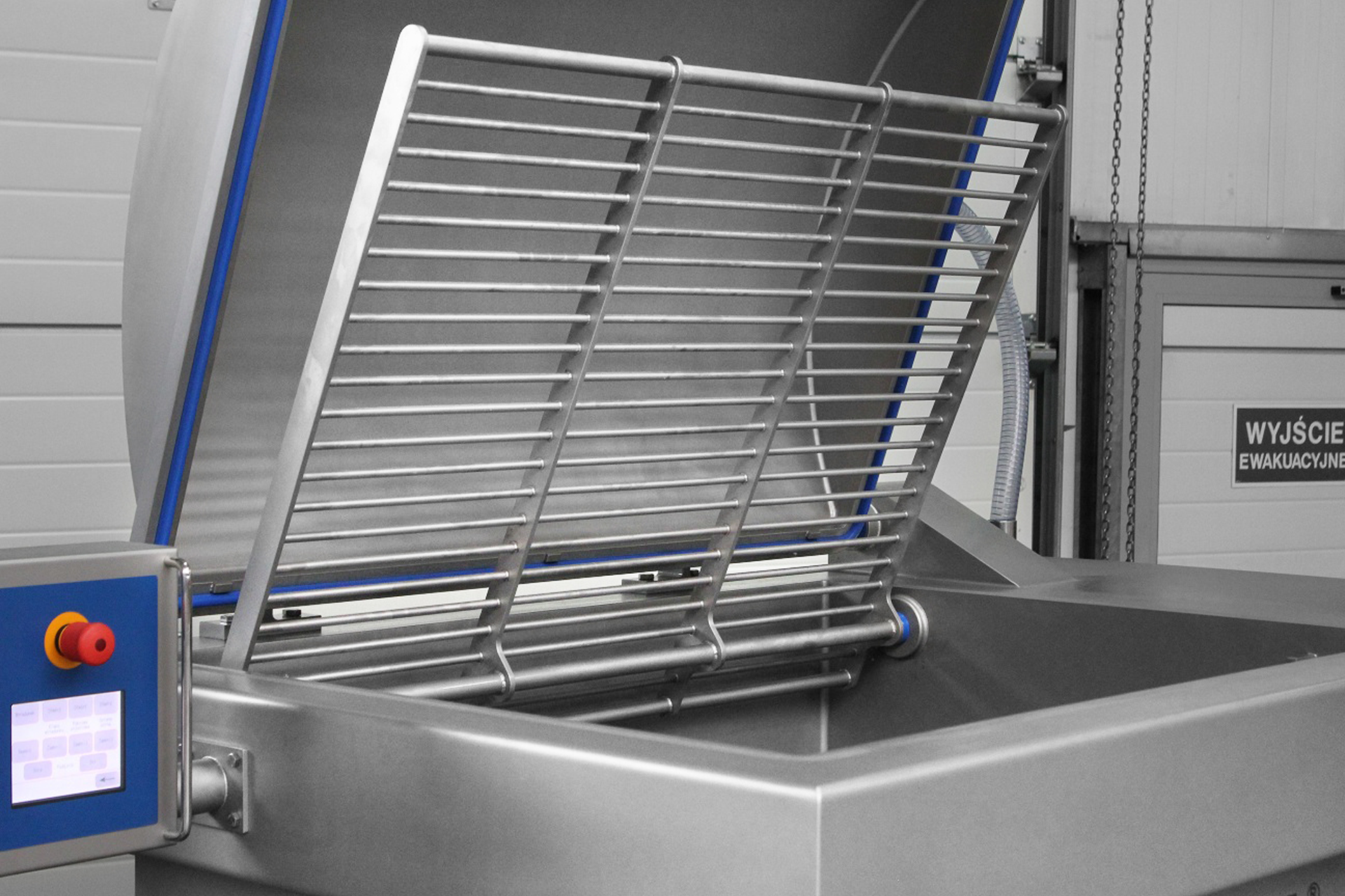

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

The MG Series mixer-grinder is designed for a wide range of applications in the food processing industry. Its innovative combination of a twin-shaft paddle mixer and a high-end grinder makes it suitable for preparing, grinding, and forming products such as pet food, sausages, burgers, and other processed foods.