Food Tumbler Equipment Solutions

Maximize the quality and color of various marinated products with tumbling equipment from BAK Food Equipment.

Introduction to Food Tumblers

What is food tumbling in food processing?

Food tumbling is a mechanical process used in food processing to enhance the quality, flavor, and texture of various products, particularly meats, seafood, and plant-based alternatives. During tumbling, products are placed in a rotating drum where they are gently agitated. This action helps distribute marinades, seasonings, and functional ingredients evenly throughout the product. Tumbling also promotes protein extraction, which is essential for binding and improving the texture of processed foods. The process is widely used for marination, ensuring that flavors penetrate deeply and consistently.

Why is tumbling important for meat, seafood, and plant-based products?

Tumbling is crucial for achieving uniformity and quality in a wide range of products, including red meat, pork, poultry, seafood, and even fruits and vegetables. For meat and seafood, tumbling accelerates the marination process, reduces processing time, and enhances tenderness and juiciness. In plant-based products, tumbling helps achieve the desired texture and flavor profile, making them more appealing to consumers. Additionally, tumbling can improve food safety by ensuring even distribution of curing agents and reducing the risk of bacterial growth. The process also offers labor savings and greater consistency compared to manual methods.

How do vacuum tumblers improve flavor, color, and texture?

Vacuum tumblers take the benefits of traditional tumbling a step further by removing air from the drum during operation. This vacuum environment allows marinades and seasonings to penetrate products more deeply and quickly, resulting in enhanced flavor and color. The absence of air also reduces oxidation, helping to preserve the natural color and freshness of the product. Vacuum tumbling is particularly effective for protein extraction, which is key to achieving the desired texture in both meat and plant-based products. The result is a more consistent, high-quality product with improved taste, appearance, and shelf life.

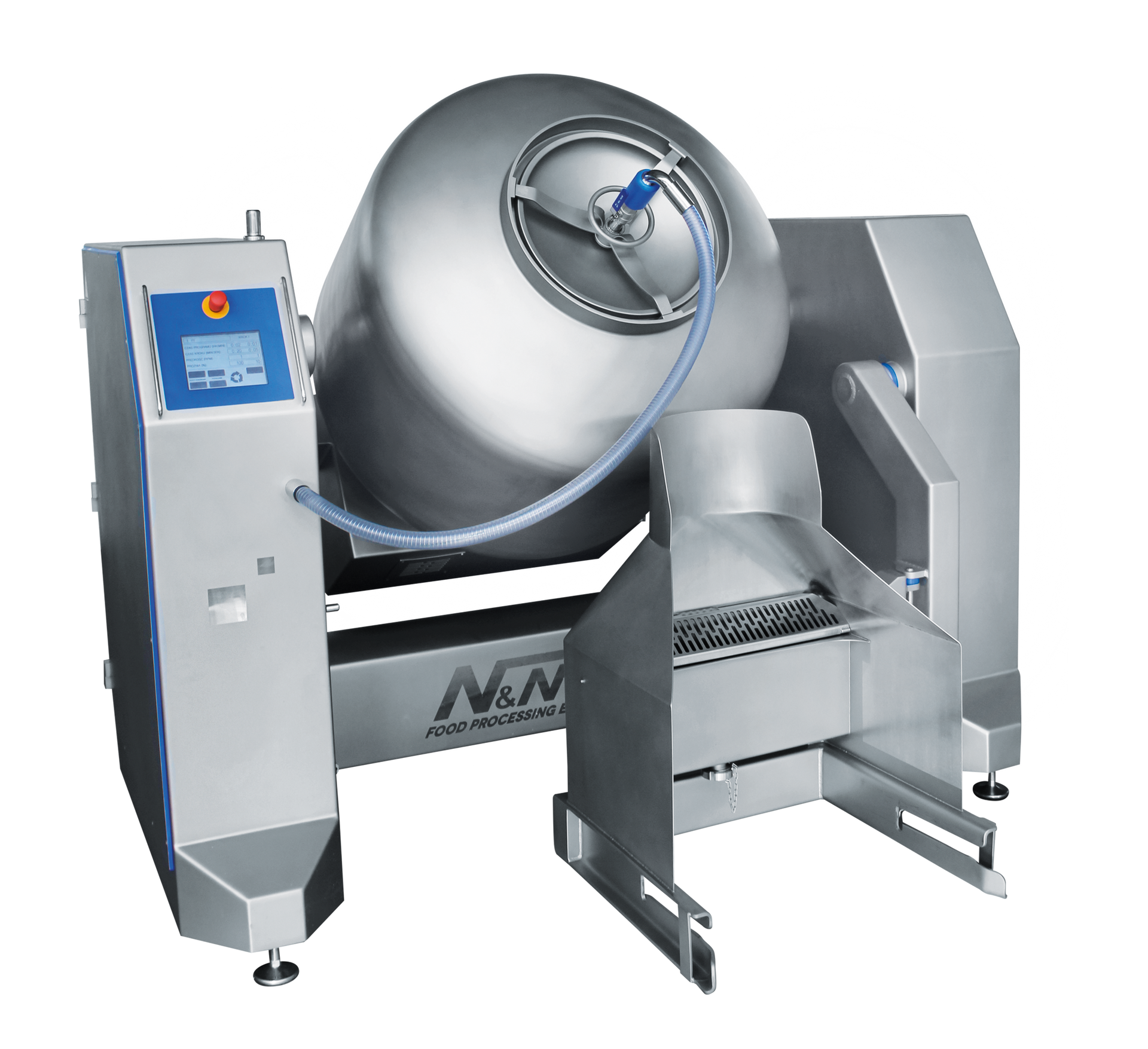

Mixing Tilting Tumblers (Series MV)

What makes mixing tumblers unique compared to standard tumblers?

Mixing tilting tumblers, such as the Series MV from BAK Food Equipment, stand out from standard tumblers due to their advanced design and versatility. Unlike traditional tumblers, which typically offer a single mode of operation, mixing tilting tumblers are engineered with asymmetrical fins inside the drum. This unique feature allows for both gentle and aggressive tumbling actions, making them suitable for a wide range of products and processing requirements. The gentle mode is ideal for delicate items like seafood or fruit, ensuring product integrity, while the aggressive mode is perfect for more robust mixing needs, such as marinating meats or blending cereal mixes. Additionally, the Series MV offers drum sizes ranging from 300 to 1,000 liters, providing flexibility for various production scales.

How does the dual-mode system improve processing?

The dual-mode system in mixing tilting tumblers significantly enhances processing efficiency and product quality. By allowing operators to switch between gentle and aggressive tumbling, processors can tailor the mixing action to the specific needs of each product batch. This adaptability not only improves the consistency of marinades and seasonings but also helps maintain the texture and appearance of sensitive ingredients. The ability to tilt the drum up to 120° further increases versatility, enabling thorough mixing and easy unloading of finished products. This feature is especially valuable in high-mix production environments where a variety of products—such as meat, seafood, fruits, vegetables, and cereal mixes—are processed on the same line. The integration of these capabilities into automated production lines streamlines workflow, reduces manual handling, and supports higher throughput, making the Series MV an ideal solution for processors seeking both flexibility and efficiency in their operations.

Semi-Automated Tumbling Lines

Why choose semi-automation instead of manual or fully automated lines?

Semi-automated tumbling lines offer a balanced approach for food processors seeking to enhance efficiency without the complexity or investment of fully automated systems. Unlike manual operations, semi-automated lines reduce the need for intensive labor, minimizing human error and improving consistency in product quality. At the same time, they provide more flexibility and control than fully automated lines, making them ideal for processors who require customization in their production processes. This makes semi-automated solutions particularly attractive for medium to large-scale operations that need to scale up production while maintaining hands-on oversight.

How do semi-automated systems improve productivity?

Semi-automated tumbling systems from BAK Food Equipment are designed with customizable size and capability, allowing processors to tailor the equipment to their specific production needs. These systems can be equipped with optional chilling or heating controls, ensuring optimal marination and product safety. By automating key steps in the tumbling process, such as loading, unloading, and cycle management, these lines significantly reduce manual labor requirements. This not only leads to labor savings but also improves yield by ensuring uniform marination and reducing product loss. The result is a more streamlined workflow, higher throughput, and consistent product quality—key advantages for processors looking to stay competitive in today’s market.

Fully Automated Tumbling Lines

What are the advantages of a fully automated system?

Fully automated tumbling lines from BAK Food Equipment offer a comprehensive solution for food processors seeking to maximize efficiency, consistency, and product quality. These systems integrate multiple processing steps—such as injection, brine mixing, and grinding—into a seamless, end-to-end automated line. By automating these processes, food manufacturers can significantly reduce manual labor requirements, which not only lowers operational costs but also minimizes the risk of human error and workplace injuries. Additionally, automation ensures a higher and more consistent product yield, as each step is precisely controlled and monitored. This level of control is especially valuable for large-scale food production, where maintaining uniformity and meeting high output demands are critical.

How do automation and data tracking benefit food processors?

Automation in tumbling lines goes hand-in-hand with advanced data tracking and reporting capabilities. Modern fully automated systems are equipped with sensors and software that monitor every stage of the process, capturing key data points such as temperature, cycle times, and ingredient ratios. This data is invaluable for traceability, allowing processors to track each batch from start to finish and quickly address any quality or safety concerns. Detailed reporting also supports compliance with food safety regulations and helps identify opportunities for process optimization. For food processors, these benefits translate into improved product safety, greater operational transparency, and the ability to make data-driven decisions that enhance overall efficiency and profitability. By investing in fully automated tumbling lines, processors position themselves at the forefront of industrial food processing equipment innovation, ready to meet the demands of modern, large-scale production environments.

Why Choose BAK Food Tumbling Equipment?

Why choose BAK Food Equipment for tumbling solutions?

BAK Food Equipment stands out as a trusted partner for food processors seeking reliable, high-performance tumbling solutions. Our tumblers are engineered to deliver consistent flavor distribution and optimal texture, ensuring that every batch meets your quality standards. Whether you’re marinating meat, poultry, seafood, or plant-based products, our equipment is designed to maximize yield, enhance moisture retention, and improve overall product quality.

What makes BAK’s machines stand out?

Our tumblers are constructed from durable stainless steel, providing long-lasting performance and easy sanitation. Each machine can be customized to meet your specific production requirements, from classic and tilting tumblers to fully automated tumbling lines. BAK Food Equipment’s solutions are proven across a wide range of industries, supporting processors of meat, poultry, seafood, and plant-based foods. We work closely with our clients to ensure that every system is tailored for their unique needs, whether you require a standard model or a fully custom solution.

Bak Food Tumbler FAQs

What is a vacuum tumbler and how does it work?

A vacuum tumbler is a specialized piece of food processing equipment designed to marinate, tenderize, and process food products under vacuum conditions. By removing air from the drum, the vacuum environment allows marinades and seasonings to penetrate deeper and more evenly into the product. This process not only enhances flavor and texture but also improves moisture retention, resulting in a higher-quality finished product. The rotating drum action ensures that every piece is uniformly coated and processed, making vacuum tumblers a valuable tool for food processors seeking consistent results.

What types of food can be processed in a tumbler?

BAK Food Equipment tumblers are engineered for versatility, accommodating a wide range of products. They are suitable for red meat, pork, poultry, and seafood, as well as plant-based foods like fruits, vegetables, and cereal mixes. This flexibility makes them ideal for processors working with both animal proteins and alternative proteins, supporting diverse production needs across the food industry.

What’s the difference between classic, tilting, and mixing tumblers?

Classic Tumblers are standard vacuum tumblers equipped with adjustable controls, making them suitable for a broad spectrum of marination and tenderization applications. Tilting Tumblers feature automated tilting systems, which simplify the loading and unloading process, especially for higher-capacity operations. Mixing Tumblers combine dual-mode rotation with mechanical tilting, offering precise control for delicate or mixed products that require gentle handling. Each type is designed to address specific production challenges and improve operational efficiency.

How do automated tumbling lines improve efficiency?

Automated tumbling lines from BAK Food Equipment integrate tumblers with other processing components such as injectors, brine mixers, conveyors, and data monitoring systems. This integration reduces manual labor, increases throughput, and ensures consistent product quality across every batch. By automating key steps in the marination and processing workflow, these lines help food processors achieve faster, more efficient production while maintaining high standards of safety and consistency.

What size tumblers are available for different production needs?

BAK offers a comprehensive range of tumbler sizes, from 300 liters up to 12,200 liters, accommodating capacities from a few hundred pounds to over 16,000 pounds. This scalability allows processors to select the right equipment for small, medium, or large production facilities, ensuring that every operation can benefit from the advantages of vacuum tumbling technology.

How do BAK tumblers improve marination and product quality?

BAK tumblers are designed to enhance marination by evenly distributing seasonings and brine throughout the product. This process improves tenderness, boosts moisture retention, and ensures consistent flavor and color. The result is a higher yield and superior product quality, regardless of the type of food being processed.