Industrial Food Mixers for Commercial Food Production

Achieve optimal ingredient mixing and blending with BAK Food Equipment’s versatile mixers designed to handle a variety of processing needs.

Over 2600 Mixers Worldwide Across 42 countries

Introduction to Industrial Food Mixers

What is an industrial food mixer and how does it work?

An industrial food mixer is a specialized piece of food processing machinery designed to blend, knead, emulsify, and sometimes cook large quantities of ingredients in commercial food production environments. Unlike household mixers, industrial food mixers are engineered for high-capacity operations, handling everything from dough and batter preparation to complex emulsions. These machines use robust motors and advanced mixing mechanisms—such as intermeshing paddles, twin shafts, or Z-type shafts—to ensure thorough and uniform mixing of ingredients. Many models, like those offered by BAK Food Equipment, are equipped with automated features and programmable control panels, allowing operators to set precise mixing times, speeds, and sequences for optimal results.

Why are they essential in commercial food production?

Industrial food mixers are essential in commercial food production because they enable manufacturers to process large volumes of product efficiently and consistently. Their versatility allows them to handle a wide range of applications, from blending dry ingredients to kneading dough and even cooking mixtures. By automating these core functions, industrial mixers reduce the need for manual labor, minimize the risk of human error, and help maintain strict quality standards. This is particularly important in industries where batch-to-batch consistency and product uniformity are critical for customer satisfaction and regulatory compliance.

How do they improve efficiency, consistency, and food safety?

Industrial food mixers significantly improve efficiency by automating the mixing process, which speeds up production and allows for continuous operation. The advanced programmable control panels found on BAK's modern mixing equipment reduce human error and ensure that each batch is mixed according to exact specifications. This automation not only enhances consistency from batch to batch but also reduces the amount of human contact with the product, which is a key factor in improving food safety. By minimizing manual handling, the risk of contamination is lowered, helping facilities meet stringent HACCP compliance and USDA/FSIS food safety requirements.

Types of Industrial Food Mixers & Applications

What are the main types of industrial food mixers?

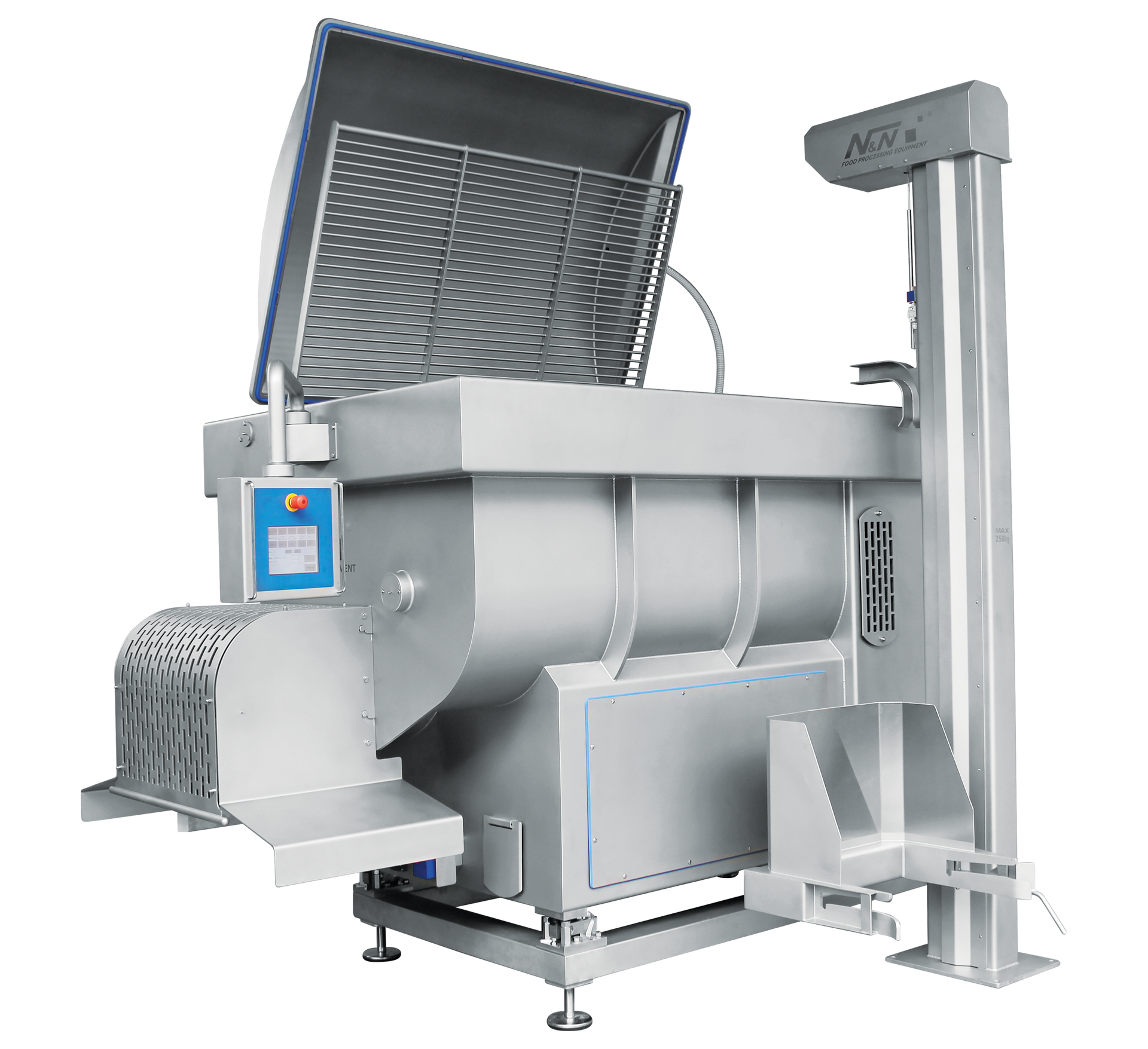

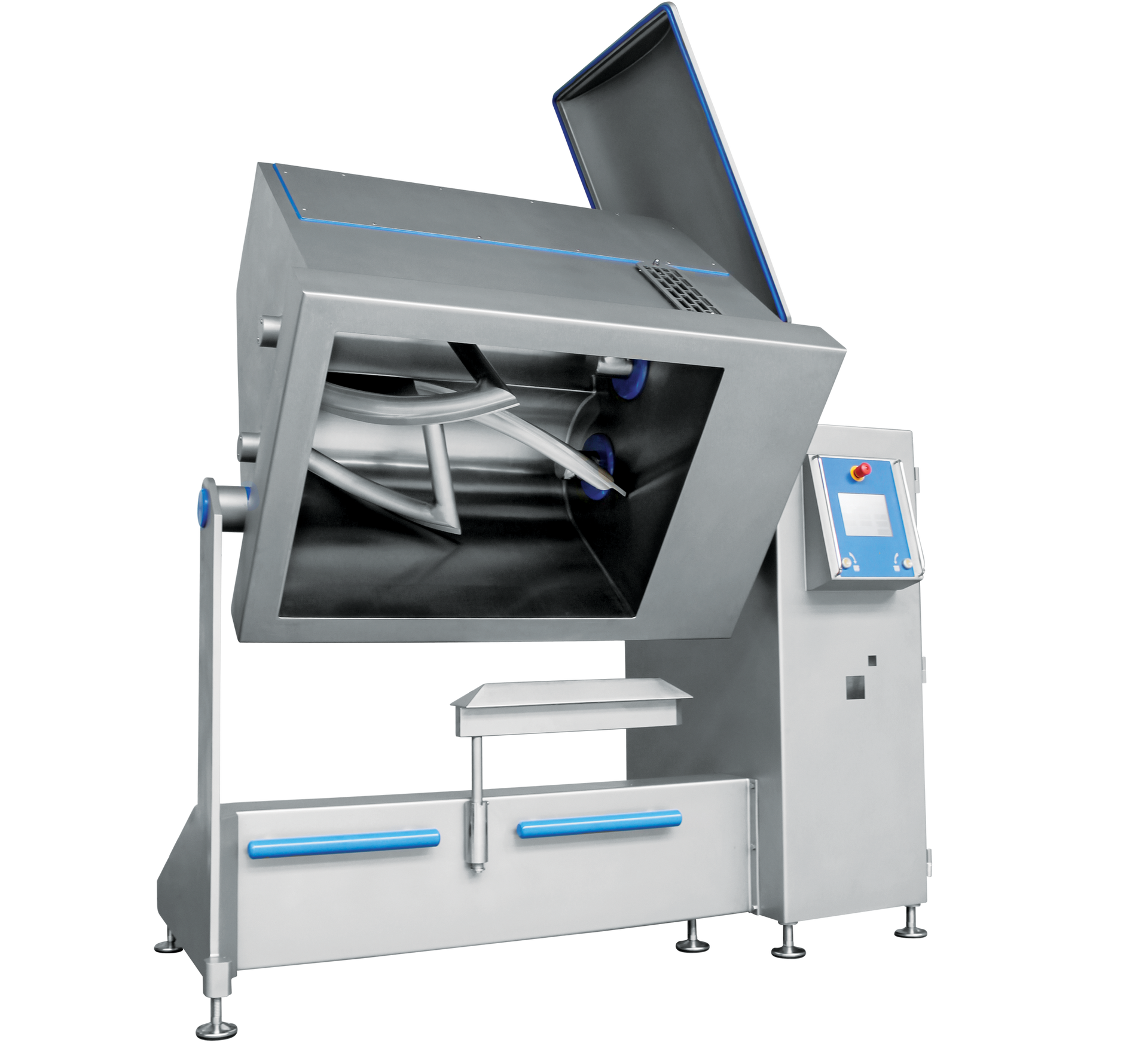

Industrial food mixers come in a variety of designs, each tailored to specific processing needs and product characteristics. The most common types include paddle mixers, ribbon blenders, Z-type mixers, industrial cooking mixers, and fully automated mixing lines. Paddle mixers and Z-type mixers are available in parallel and intermeshing shaft designs, while ribbon mixers come with a single shaft.

Which mixer type is best for specific food applications?

The optimal mixer type depends on the product being processed. Paddle mixers are the most versatile mixer that is ideal for gently blending delicate ingredients or products with larger particulates, such as meat blends or salads, where maintaining product integrity is crucial. Ribbon blenders excel at mixing powders and dry ingredients as well as liquid and semi-liquid products. Z-type mixers, available in both intermeshing and parallel shaft versions, are well-suited for high-viscosity doughs and dense meat emulsions, making them a staple in bakery and processed meat production.

How do design differences (paddle, ribbon, Z-type) impact mixing results?

The design of a mixer directly influences its mixing action and the quality of the final product. Paddle mixers use broad, flat paddles to gently move ingredients, minimizing shear and preserving texture—ideal for sensitive or chunky products. Ribbon blenders feature helical ribbons that create a counter-flow, ensuring rapid and uniform mixing of powders and granular materials. Z-type mixers, with their intermeshing or parallel Z-shaped shafts, provide intensive kneading and blending, making them effective for tough, sticky, or high-viscosity mixtures. Batch size, viscosity, and product sensitivity are key considerations when selecting a mixer design. For example, high-viscosity doughs require the robust action of a Z-type mixer, while large batches of dry ingredients benefit from the efficiency of a ribbon blender.

Key Features of Industrial Food Mixers

Which technical specifications matter most?

When evaluating industrial food mixers, several technical specifications are critical to ensuring optimal performance and product consistency. The mixing action—whether paddle, ribbon, or Z-type—directly influences the thoroughness and speed of ingredient integration. Motor power is another essential factor, as it determines the mixer’s ability to handle dense or high-volume batches without strain. Batch capacity must align with your production requirements, supporting high-volume food production while maintaining efficiency. The programmable control panels on the equipment offer precise control over mixing cycles, allowing for repeatable results and flexibility across different recipes. Material construction, particularly the use of high-grade stainless steel, is vital for both durability and compliance with food safety standards.

How do speed controls, capacity, and materials affect output?

Variable speed mixers provide the flexibility to adjust mixing intensity based on the product being processed, which is crucial for achieving the desired texture and consistency. The ability to fine-tune speed not only enhances product quality but also reduces processing times and energy consumption. Capacity is equally important; selecting a mixer with the right batch size ensures efficient throughput and minimizes downtime between cycles. The use of stainless steel food mixers is standard in the industry due to their resistance to corrosion, ease of cleaning, and long service life, all of which contribute to consistent output and reduced risk of contamination.

Why are durability, sanitation, and ease of maintenance important?

Durability ensures that mixers can withstand the rigors of continuous operation in demanding environments, reducing the frequency and cost of repairs. Sanitation is paramount in food processing, making sanitary food processing equipment with smooth surfaces and minimal crevices is essential to prevent bacterial growth. Features such as CIP cleaning systems and quick-disassembly designs streamline cleaning and maintenance, supporting both hygiene and high equipment uptime. These attributes not only help meet regulatory requirements but also protect product integrity and operator safety, making them indispensable in modern food processing operations.

What additional options are available for industrial mixers?

BAK Food Equipment offers a comprehensive range of optional add-ons and customizations for their mixers to meet diverse production needs. These options include fully sealed covers that ensure airtight operation, openwork covers for flexible loading, and temperature monitoring systems to maintain precise control over the mixing environment. Cooling and heating jackets are available to regulate product temperature during processing, as well as liquid nitrogen or CO2 injection systems for cooling. Steam injections can also be used for heating or cooking. Additional features such as load cells provide accurate weight measurement, automated loaders facilitate seamless product transfer, and an easy-clean system simplifies maintenance. Polished bowls and shafts enhance hygiene and product quality, and water dosage systems enable precise water addition during mixing.

Choosing the Right Food Mixer for Your Operation

How to match a mixer to production needs?

Selecting the right food mixer begins with a clear understanding of your production requirements. Determining the necessary industrial mixing capacity is essential—this means evaluating your throughput targets and the volume of product you need to process within a given timeframe. For high-volume operations, larger mixers such as parallel twin shaft mixers or intermeshing paddle mixers may be appropriate, as they are designed to handle substantial batches efficiently. For smaller or more specialized production runs, a single shaft double ribbon contra flow mixer might be more suitable. Additionally, the type of product formulation and its viscosity play a critical role in mixer selection. For example, dense or sticky mixtures may require robust Z-type shaft mixers, while powders and liquids are more suited for a ribbon mixture.

What should be considered in plant layout and workflow?

When integrating a new mixer into your facility, careful attention must be paid to food production line planning and commercial kitchen workflow optimization. Space constraints are a primary consideration—ensure that the chosen mixer fits comfortably within your available floor space and allows for safe, efficient movement of personnel and materials. Power requirements should also be assessed to confirm compatibility with your facility’s electrical infrastructure. Furthermore, consider how the mixer will integrate with other processing equipment, such as conveyors, feeders, or automated production lines, to create a seamless workflow. Proper planning in these areas not only maximizes operational efficiency but also supports food safety and quality standards throughout your production process.

Cost & Budget Planning

What is the typical price range?

The price of commercial mixers can vary significantly based on several key factors, including capacity, level of automation, brand reputation, and build quality. At BAK Food Equipment, our mixer portfolio ranges from compact, single-shaft models suitable for smaller operations to large-scale, fully automated mixing lines designed for high-volume food manufacturers. Entry-level mixers may start in the low five-figure range, while advanced, high-capacity automated systems can reach into the six figures. The choice between intermeshing paddle mixers, twin shaft mixers, or specialized Z-type shaft mixers will also influence the final investment.

How to calculate total cost of ownership?

When planning an investment, it’s essential to look beyond the initial purchase price and consider the total cost of ownership (TCO). This includes not only the upfront cost but also ongoing expenses such as maintenance, energy consumption, labor savings from automation, and potential downtime. Automated mixing systems from BAK Food Equipment are engineered for durability and efficiency, which can translate into lower operational costs and reduced labor requirements over time. By factoring in these operational savings, food manufacturers can better assess the long-term food processing ROI of their equipment investment.

What financing or leasing options exist?

To support capital equipment budgeting, BAK Food Equipment offers a third-party financing solution. This option can help businesses manage cash flow, preserve working capital, and upgrade to the latest technology without a large upfront expenditure. Our team can guide you through available programs to find the best fit for your production goals and budget constraints, ensuring your investment in industrial mixing equipment aligns with your long-term business strategy.

Maintenance & Care of Mixers

How to extend the life of a mixer?

Extending the life of a commercial mixer begins with a robust preventive maintenance schedule. Regularly scheduled inspections and servicing help identify potential issues before they become costly problems. Lubrication of moving parts, such as gears and bearings, is essential to minimize friction and wear. For chain-driven mixers, periodic checks and adjustments of tension ensure optimal performance and prevent premature failure. Additionally, following manufacturer-recommended industrial equipment service plans can help maintain the integrity and efficiency of your mixer over time.

What maintenance is essential for performance and safety?

Routine maintenance is critical for both the performance and safety of industrial mixers. Mixer cleaning procedures should be performed after each use to prevent ingredient buildup and ensure sanitary compliance, which is especially important in food processing environments. All accessible surfaces, paddles, and shafts should be thoroughly cleaned and sanitized according to industry standards. Regularly inspect the mixer for signs of wear, such as unusual noises, vibration, or visible damage to chains, gears, or seals. Addressing these issues promptly can prevent unexpected breakdowns and maintain a safe working environment. Adhering to preventive maintenance protocols and keeping detailed service records will help ensure your mixer operates reliably and safely for years to come.

Conclusion & Next Steps

Why invest in a high-quality industrial food mixer now?

Investing in a high-quality industrial food mixer is a strategic decision that can transform your food processing operations. Modern mixers, such as those offered by BAK Food Equipment, are engineered for versatility and reliability, handling a wide range of processing needs from doughs to batters and beyond. By choosing a robust, automated mixing system, you ensure consistent ingredient blending, reduce manual labor, and minimize the risk of human error. This not only streamlines your production but also helps maintain compliance with food safety standards and regulations.

What is the long-term impact on productivity and profitability?

The long-term impact of integrating a high-quality industrial food mixer into your production line is significant. Enhanced efficiency means faster batch processing and reduced downtime, allowing you to scale up production without sacrificing quality. Consistency in mixing leads to uniform product quality, which is essential for building brand reputation and customer trust. Automated systems also contribute to better resource management, reducing waste and optimizing ingredient usage. Over time, these benefits translate into a strong return on investment (ROI) through lower operational costs, improved throughput, and increased profitability. Partnering with a trusted commercial food equipment supplier like BAK Food Equipment ensures you have access to advanced food processing machinery and ongoing support, maximizing the value of your investment.

Industrial Food Mixer FAQs

What is an industrial food mixer?

An industrial food mixer is a robust, heavy-duty machine engineered for large-scale food production environments. These mixers are designed to blend, knead, emulsify, or even cook ingredients in high volumes, ensuring consistent product quality and efficient processing. Industrial mixers are built to meet stringent food safety standards, making them essential for manufacturers who require reliability and compliance in their operations.

What types of industrial food mixers are available?

BAK Food Equipment offers a comprehensive range of industrial mixers to suit diverse processing needs. Our lineup includes intermeshing paddle mixers, parallel twin shaft mixers (available with paddle or ribbon configurations), intermeshing and parallel Z-type shaft mixers, parallel twin shaft cooking mixers, single shaft double ribbon contra flow mixers, and fully automated mixing lines. Each mixer type is optimized for specific applications, such as dough preparation, sauce blending, meat processing, confectionery, and pet food production. This variety ensures that processors can select the ideal mixer for their unique product requirements.

Which industries use industrial mixers?

Industrial mixers from BAK are utilized across a wide spectrum of food processing sectors. Key industries include meat and poultry processing, bakery and confectionery, dairy, sauces and prepared foods, baby food, and pet food manufacturing. The versatility and scalability of our mixers make them suitable for both specialized and high-volume production environments. For more information on specific uses, visit our Applications page.

What capacity range do your mixers cover?

Our mixers are available in a broad range of capacities to accommodate different production scales. BAK mixers start at 180 liters (approximately 298 lbs capacity) for smaller operations and scale up to 8,000 liters (about 13,250 lbs capacity) for high-volume production lines. This flexibility allows processors to choose equipment that matches their throughput requirements and facility space.

What are the benefits of using vacuum mixing?

Vacuum mixing technology offers several advantages in food processing. By removing air bubbles from the mix, vacuum mixers improve protein extraction, enhance the distribution of spices and liquids, and control product density. This results in smoother emulsification and a more uniform final product, which is especially important before filling or forming processes. Vacuum mixing is particularly beneficial in applications where texture and consistency are critical.

How do industrial mixers improve food safety?

Food safety is a top priority in mixer design. BAK mixers are constructed from stainless steel and feature sanitary design elements such as enclosed mixing chambers, hydraulic unloading, and Clean-in-Place (CIP) systems. These features minimize contamination risks and help processors meet HACCP and USDA/FSIS standards. Regular maintenance and proper sanitation further ensure compliance and product safety.

How do I choose the right mixer for my operation?

Selecting the right mixer involves evaluating several factors: the type and viscosity of your product, desired batch size, throughput targets, available facility space, and how the mixer will integrate into your production line. BAK Food Equipment’s team of experts can help assess your specific needs and recommend the most suitable mixer configuration. For tailored advice, contact us directly.

What is the typical cost of an industrial food mixer?

The cost of an industrial mixer varies depending on its size, capacity, level of automation, and optional features such as vacuum systems or heating jackets. While the initial investment can be significant, many processors see a rapid return on investment through labor savings, increased efficiency, and reduced downtime. BAK offers financing and leasing options to help make these solutions accessible.

How should mixers be maintained?

Routine preventive maintenance is essential for optimal performance and longevity. This includes regular lubrication, inspection of gears and chains, and thorough cleaning. Many BAK mixers are equipped with CIP systems and quick-disassembly parts, making sanitation straightforward and efficient. Adhering to a maintenance schedule not only extends equipment life but also ensures ongoing compliance with food safety standards. For more details, visit our Service page.

Can mixers be customized?

Yes, BAK mixers can be tailored to meet specific processing requirements. Customization options include sealed or openwork covers, heating or cooling jackets, water dosage systems, load cells, and integration with automated lines featuring grinders, emulsifiers, and other equipment. Our engineering team works closely with clients to deliver solutions that fit seamlessly into their production processes.