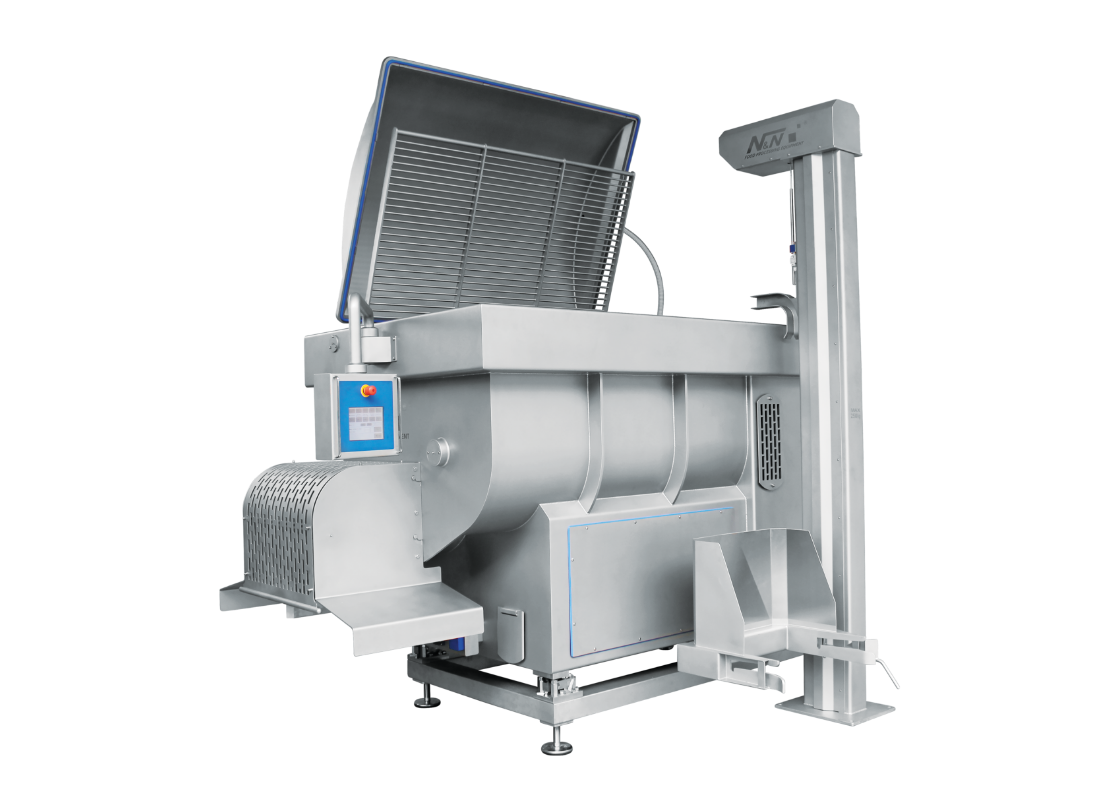

Series MHM

Mechanical Brine Injectors

Needles

21 - 204

Needles

Conveyor Width

13 - 21

In.

- Integrated Brine Tank and Filtration System: Equipped with an under-machine brine tank that supplies the injector, with excess brine filtered and recirculated back into the tank for efficient operation.

- Bone-In or Boneless Capability: The machine is designed to efficiently handle both bone-in and boneless products, offering versatility for various processing needs.

- Advanced Parameter Control: Easily adjust variable injection parameters such as injection head speed and brine pump pressure, allowing for any value within the machine’s range. Conveyor speed offers 3 or 4 preset settings, depending on the model, to ensure optimal performance tailored to your specific needs.

- Needle Configuration:

Each needle socket can be fitted with a single, double, triple, or quadruple needle, allowing customization based on specific needs.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store custom programs by adjusting variables such as injection head speed and brine pump pressure.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient. The needle head and individual needles can easily be removed for cleaning and maintenance.

Technical Information

Applications

NOMA Mechanical Brine Injectors are designed for brine injection of a variety of products, including bone-in or boneless meats, whole poultry and poultry parts, as well as fish and fish fillets. This system ensures consistent flavor and moisture throughout.

Clarion Locker

"Before the NOMA injector, we spent two grueling days on manual brine injection. Now, it’s down to under an hour—and the results are so impactful, my wife jokes that she’d rather give me up than give up this machine.” – Owner

You Might Also Like

More About Brine Injector Machines

What is a brine injector machine?

A brine injector machine is designed to inject a brine solution directly into meat, poultry, and fish products. This equipment plays a crucial role in enhancing the moisture content, flavor, and overall yield of these products. By delivering a consistent and controlled amount of brine, the machine ensures that the final product is juicy, flavorful, and has improved texture.

How do brine injector machines work?

Brine injector machines operate by using multiple needles that penetrate the product to deliver the brine solution evenly throughout. The Series MHM Mechanical Brine Injectors from BAK Food Equipment exemplify this technology with needle configurations ranging from 21 to 204 needles, adaptable to various product sizes and types. These machines feature an integrated brine tank and filtration system that recirculates excess brine for efficient operation. Operators can adjust injection parameters such as injection head speed, brine pump pressure, and conveyor speed through an advanced programmable control panel, allowing precise control over the injection process. The needles can be customized with single, double, triple, or quadruple configurations to meet specific processing needs. The entire system is constructed from stainless steel, ensuring durability and ease of cleaning and maintenance.

Why are brine injector machines important for meat, poultry, and fish processing?

Brine injector machines are vital in the meat processing industry because they significantly improve product quality and processing efficiency. By injecting brine, these machines enhance moisture retention, which leads to juicier and more tender meat, poultry, and fish. This process also boosts flavor uniformly throughout the product, ensuring a consistent taste experience. The versatility of the Series MHM injectors allows them to handle bone-in and boneless products effectively, making them indispensable equipment in modern meat processing operations. Their robust industrial-grade construction and advanced control features make them reliable and adaptable to various production requirements.

Benefits of Using a Brine Injector Machine

What are the advantages of using mechanical brine injectors in processing plants?

Mechanical brine injectors offer numerous advantages in meat and fish processing plants. They ensure consistent flavor and moisture distribution throughout the product, which is critical for maintaining high food quality control standards. By precisely injecting brine, these machines improve moisture retention, resulting in juicier and more flavorful meat. This consistency in flavor and texture enhances the overall eating experience and meets consumer expectations. These machines provide versatility by efficiently handling a wide range of proteins, including beef, pork, poultry, and fish, whether bone-in or boneless. This flexibility allows processors to use a single piece of equipment for multiple product lines.

How do they impact product quality and yield?

Mechanical brine injectors positively impact product quality by delivering uniform brine distribution, which enhances flavor consistency and moisture retention. This uniformity is difficult to achieve with manual methods, making mechanical injection a superior choice for maintaining high standards.

From a yield perspective, the precise control over injection volume—ranging typically from 6% to 55%—helps maximize retention of brine within the product. This reduces weight loss during cooking and increases the final product yield, directly improving profitability. The advanced programmable control panels on machines like the BAK Food Equipment MHM series allow operators to fine-tune injection parameters such as injection head speed and brine pump pressure, optimizing the process for different products and production goals.

Moreover, these machines reduce manual labor and speed up production by automating the injection process. This not only increases throughput but also enhances food safety and compliance by minimizing human contact and ensuring consistent, controlled processing conditions. The durable, stainless steel construction and easy-to-clean design further support hygienic operations and efficient maintenance.

Choosing the Right Brine Injector Machine For Your Plant

What are the available Series MHM models?

BAK Food Equipment offers three main models in the Series MHM Mechanical Brine Injectors line, designed to meet varying production needs. These include the MHM 21/84, MHM 39/156, and MHM 68/204. Each model differs primarily in the number of needle sockets, needle range, conveyor width, and overall machine dimensions, allowing processors to select the best fit for their specific application. The MHM 21/84 features 21 needle sockets with a needle range of 21 to 84 and a conveyor width of 12.8 inches. The MHM 39/156 increases capacity with 39 needle sockets, a needle range of 39 to 156, and a conveyor width of 14.8 inches. The largest model, MHM 68/204, offers 68 needle sockets, a needle range of 68 to 204, and a conveyor width of 20.7 inches.

How do processors choose the right size and capacity?

Selecting the appropriate Series MHM model depends largely on the production volume and product type. Processors should consider the needle range and conveyor width in relation to their throughput requirements. For smaller to medium production volumes, the MHM 21/84 provides a compact yet efficient solution. Medium to larger operations may find the MHM 39/156 suitable due to its increased needle count and conveyor size, accommodating higher volumes and larger product sizes. For high-capacity plants requiring maximum throughput, the MHM 68/204 offers the largest needle configuration and conveyor width, ideal for processing substantial quantities of bone-in or boneless meats, poultry, and fish. Additionally, the machine dimensions and weight should be considered to ensure proper integration into existing production lines.

For very large and complex operations, processor should consider BAK’s

SAS servo-driven injectors that are larger and better suited to high-volume production lines.

Easy Maintenance & Hygiene

How is cleaning handled in the Series MHM?

The Series MHM Mechanical Brine Injectors are designed with ease of cleaning and maintenance as a priority. The needle head and individual needles are fully removable, allowing operators to quickly disassemble these components for thorough cleaning. This feature significantly reduces downtime during routine sanitation procedures. Additionally, the entire machine is constructed from stainless steel, which is inherently resistant to corrosion and facilitates easy sanitation. The design also incorporates an integrated brine tank and filtration system that recirculates excess brine, helping maintain cleanliness and operational efficiency.

Why does sanitation matter in brine injection?

Sanitation is critical in brine injection to ensure food safety compliance and prevent contamination during meat processing. Using sanitary food machinery like the Series MHM, which is built from stainless steel equipment, helps maintain hygienic conditions by resisting corrosion and simplifying cleaning processes. Proper sanitation minimizes the risk of bacterial growth and cross-contamination, which is essential for producing safe, high-quality meat products. The Series MHM’s design minimizes downtime for routine maintenance, enabling processors to uphold strict hygiene standards without sacrificing productivity.

Why Choose the Series MHM?

Why choose the Series MHM Mechanical Brine Injector?

The Series MHM Mechanical Brine Injector stands out as a premier choice for industrial meat processing due to its combination of durability, programmability, and versatility. Constructed entirely from stainless steel, it offers exceptional durability and long-lasting performance even in the most demanding food processing environments. This robust build ensures that processors can rely on consistent operation day after day.

What makes it stand out for processors?

One of the key features that distinguishes the Series MHM is its advanced programmable control panel. The intuitive touch screen interface allows operators to easily create and store custom injection programs by adjusting critical variables such as injection head speed and brine pump pressure. This level of control helps processors achieve consistent quality and optimal yield by tailoring the injection process to specific product requirements. Additionally, the integrated brine tank and filtration system recirculate excess brine, promoting efficient operation and reducing waste. Conveyor speed settings and injection volume can be precisely controlled, further enhancing processing efficiency.

Versatility is another hallmark of the Series MHM. It is designed to handle both bone-in and boneless products efficiently, making it suitable for a wide range of product types. The needle configuration is highly customizable, with each needle socket capable of fitting single, double, triple, or quadruple needles, allowing processors to adapt the machine to their unique processing needs.

Sanitation and maintenance are also prioritized in the design. The needle head and individual needles can be easily removed for thorough cleaning, ensuring compliance with food safety standards and minimizing downtime.

To learn more about specifications, pricing, or to discuss how the Series MHM can fit into your production line, we encourage you to contact BAK Food Equipment directly. Our team is ready to provide detailed information and support to help you achieve consistent quality, yield, and efficiency in your meat processing operations.

Brine Injector Machine FAQs

What is the purpose of a brine injector machine?

A brine injector machine is designed to inject brine solutions directly into meat, poultry, or fish products. This process enhances flavor, improves texture, and increases moisture retention, resulting in a higher quality final product. By distributing the brine throughout the product, the machine ensures consistent seasoning and juiciness.

Can the Series MHM brine injector handle both bone-in and boneless products?

Yes, the Series MHM mechanical brine injector is engineered with spring-loaded needles that will retract out of the product if they come into contact with a bone.

How many needles can the Series MHM brine injector support?

Depending on the specific model, the Series MHM supports from 21 up to 204 needles. Each needle socket can be customized with single, double, triple, or quadruple needles to meet different injection requirements. This flexibility allows processors to tailor the injection pattern and volume to their product specifications.

What are the benefits of using a mechanical brine injector instead of manual brining?

Mechanical brine injection offers several advantages over manual methods. It provides precise and consistent injection volumes, which leads to improved product quality and higher yields. Additionally, it significantly reduces labor costs and processing time. The integrated brine tank and filtration system in the Series MHM recirculates excess brine, enhancing operational efficiency.

How easy is it to clean and maintain the Series MHM?

The Series MHM is designed with ease of cleaning and maintenance in mind. The needle head and individual needles can be quickly removed for thorough cleaning. Constructed entirely from stainless steel, the machine supports sanitary operation and low maintenance, which is critical in industrial food processing environments.